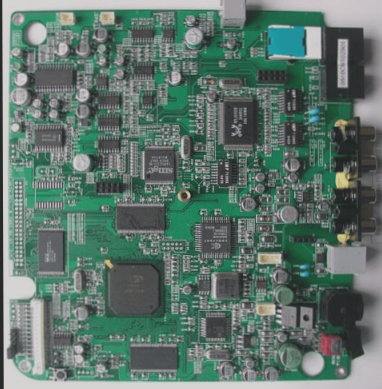

Understanding Industry 4.0 and Its Impact on PCBA Processing

Industry 4.0: A Global Transformation

In recent years, Industry 4.0 has gained momentum in the PCBA processing industry, revolutionizing traditional manufacturing practices. But what exactly is Industry 4.0?

The Influence of Industry 4.0

Industry 4.0 extends beyond industrial realms, with a vast scope that challenges conventional boundaries. This transformative concept has the potential to reshape the global landscape, impacting various sectors worldwide.

China’s Embrace of Industry 4.0

China’s interest in Industry 4.0 surged following Premier Li Keqiang’s visit to Germany in 2014. The “China-Germany Cooperation Action Program” sparked a strategic focus on intelligent manufacturing, aligning with Germany’s Industry 4.0 principles.

Made in China 2025 and Intelligent Manufacturing

“Made in China 2025” emphasizes intelligent manufacturing, mirroring the core concepts of Industry 4.0. The integration of cyber-physical systems (CPS) in China’s manufacturing vision echoes Germany’s industrial strategies.

The Evolution of Chinese Industries

- The Ministry of Industry and Information Technology’s initiatives align domestic industries like SMT chip and PCBA processing with Industry 4.0 standards.

- “Made in China 2025” focuses on long-term strategies to elevate China’s industrial prowess, drawing inspiration from Germany’s industrial advancements.

- By integrating information technology into manufacturing, China aims to enhance production processes, enabling mass customization and industry innovation.

Transitioning to Industry 4.0

Companies in SMT chip and PCBA processing sectors are embracing Industry 4.0 to enhance customer service and elevate industry standards, aligning with China’s vision of national rejuvenation.