SMD (Solder Mask Defined) and NSMD (Non-Solder Mask Defined) refer to the methods of exposing copper pads on a printed circuit board (PCB). This seemingly minor detail in PCB pad design, once overlooked, has gained increasing importance as electronic components shrink and solder joints become smaller.

What are SMD and NSMD?

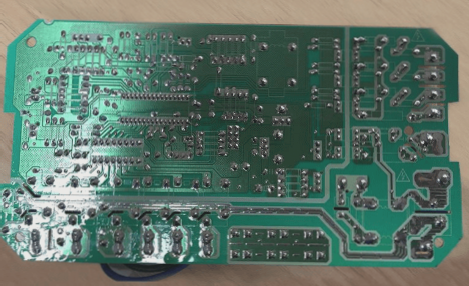

Currently, both pads and traces are primarily made from copper foil. However, not all of the copper foil is exposed during PCB design; only the pads that need to be connected or soldered are exposed to prevent potential issues such as moisture-induced short circuits. To achieve this, a material known as Soldermask is used to cover the copper foil that should not be exposed. The accuracy and capability of soldermask printing are therefore crucial, especially for small solder pads.

SMD

SMD (Solder-Mask Defined) uses soldermask to cover a larger area of copper foil, with the copper exposed where the soldermask is not present — this exposed area forms the pad. The size of the solder pad is determined by the size of the soldermask opening, which is why it is called a Solder-Mask Defined Pad.

NSMD

NSMD (Non-Solder Mask Defined), also known as Copper Defined Pad Design, is a design technique in which the copper foil is smaller than the soldermask opening, resembling an island in a lake. In this design, the size of the solder pad is primarily determined by the copper foil dimensions, and therefore it is referred to as Copper Defined Pad Design or Non-Solder Mask Defined.

Advantages and Disadvantages of SMD and NSMD

Advantages of SMD

- SMD solder pads have regular shapes that are not affected by trace routing, making them suitable for small component pads like 0402, 0201, and 01005.

- SMD solder pads are less prone to tearing or detachment during rework because the actual copper area is relatively larger compared to NSMD. Additionally, the soldermask covers part of the pad, creating a stronger bond between the pad and the FR4 substrate.

Disadvantages of SMD

- Since the soldermask covers part of the solder pad, the stencil thickness becomes one soldermask layer thicker than in NSMD, which increases solder volume and can make the pads more prone to short circuits during manufacturing. Special attention is required in this regard.

- The soldermask reduces the available copper area for soldering and decreases the space between adjacent pads, which can complicate the trace widths and impact the use of through-holes, making PCB layout more challenging.

- The solder strength of SMD pads tends to be weaker because the effective solderable area is smaller, and the soldermask around the pad can affect solder wetting due to thermal expansion and contraction during reflow soldering.

Advantages of NSMD

- NSMD solder pads have a larger solderable area, as both the top surface and vertical sides of the copper foil can be wetted with solder. This results in stronger solder joints.

- The greater spacing between pads (compared to SMD) allows for wider trace widths and greater flexibility with through-holes, making PCB layout easier.

Disadvantages of NSMD

- The shape of NSMD solder pads can be influenced by trace routing, leading to variations in pad size, which can sometimes result in the “tombstone” effect. It is recommended to use SMD pads for flexible boards and small devices (less than 0402), while NSMD is better suited for larger components. For BGAs, a mixed approach may be used, with functional pins designed as SMD and fixed pins designed as NSMD.

- NSMD pads are more isolated, making them more prone to detachment during repair or rework.

- Flux residue and solder balls can accumulate in areas not covered by soldermask, potentially causing issues.

If you have any questions about PCBs and PCBA, please feel free to contact me at info@wellcircuits.com.