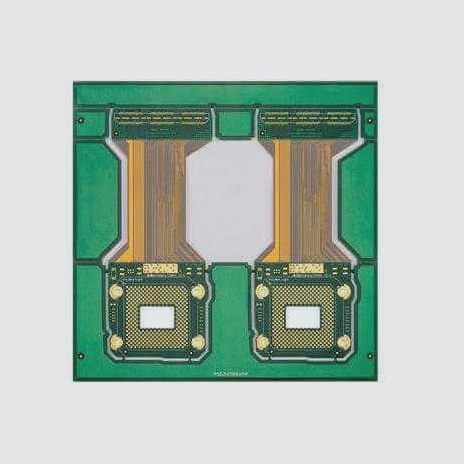

**Whether performing AC-DC or DC-DC conversion on a PCB board, switching power supply layouts are common in high-voltage designs and must be constructed carefully.** Although this system is very common, it is prone to radiated EMI due to the rapid changes in voltage and current during switching. Designers often struggle to adapt existing designs to new systems because even small changes in one area can create EMI problems that are difficult to diagnose. With proper placement and routing, noise can be mitigated to prevent significant issues on the SMPS output. Low-voltage converters are available as ICs in various form factors, but high-voltage converters require discrete components on dedicated boards. Here are some important SMPS PCB layout tips to help you keep components cool and prevent noise issues in your system.

**Noise and Thermal Issues in SMPS PCB Board Layout** There is no fix: any SMPS will generate moderate high-frequency noise due to the switching action of the transistor driver. Essentially, you are converting low-frequency ripple (e.g., from a full-wave rectifier during AC-DC conversion) into high-frequency switching noise. Although this conversion results in a more stable DC output, there are still two significant sources of noise: direct switching noise from the switching elements and transient noise elsewhere in the system. Noise can manifest at the SMPS unit’s output as conducted and radiated noise. While diagnosing the cause of each problem can be challenging, these two types of noise can be easily distinguished.

Another design challenge in SMPS PCB layout is the heat generated on the board. While factors such as PWM frequency, duty cycle, and rise time influence this, effective thermal management strategies are still crucial. With these two challenges in mind, let’s examine some details to focus on in SMPS PCB layout.

**Thermal Management** An ideal SMPS would dissipate zero power, although this is not practical. Your switching transistors (and the input transformer for AC-DC conversion) will dissipate most of the heat. Even though switching power supply topologies can achieve 90% efficiency, power MOSFETs can still generate significant heat during switching. A common practice is to place heat sinks on critical switch components and ensure they are connected to the ground plane to avoid introducing new EMI. In high-voltage/high-current power supplies, these heat sinks can be quite large. To enhance cooling, consider installing fans in the chassis, but be sure to follow best practices for powering these fans to prevent new EMI issues.

**Some SMPS PCB Board Layout Tips** Your layout will contribute to thermal management to some extent, but it is a more significant factor in determining EMI susceptibility. Typically, conducted noise is managed using EMI filters on the input and output circuits. As with many EMI issues in high-speed/high-frequency systems, the stackup of your PCB is crucial in resisting radiated EMI. The relevant frequency range for SMPS operation is ~10 kHz to ~1 MHz, so radiated EMI will induce noise. Therefore, place the ground plane in the stackup directly below the surface layer, along with all power components, to ensure low loop inductance of the surface circuit. Any noise signal propagating to the output is usually filtered out at the output stage.

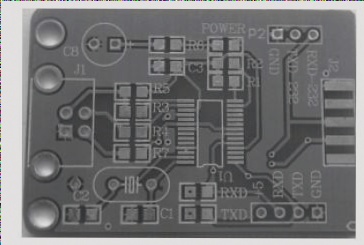

**Transient Ringing** Transients present a more challenging problem as they relate to your stackup, routing, vias, and decoupling/impedance issues. As with high-speed designs, avoid routing copper carrying switching signals across gaps in the ground plane, as this can create an antenna structure that radiates strongly during transients. These transients tend to be high-frequency (ranging from 10 to 100 MHz). The problem with transient ringing is primarily an impedance management issue. High impedance results in significant voltage ripple. Place components with the correct land pattern to minimize impedance in the board PDN. Examples of good and bad pads for your components are shown below.

**The Quality of the Components in the Layout** Generally, avoid isolated islands in your layout. Use decoupling capacitors to connect any power islands containing control circuitry or passive components back to the ground plane. Be cautious when placing vias on the PCB, as you want to avoid creating unintended gaps or sockets in the ground plane.

**Noise and Thermal Issues in SMPS PCB Board Layout** There is no fix: any SMPS will generate moderate high-frequency noise due to the switching action of the transistor driver. Essentially, you are converting low-frequency ripple (e.g., from a full-wave rectifier during AC-DC conversion) into high-frequency switching noise. Although this conversion results in a more stable DC output, there are still two significant sources of noise: direct switching noise from the switching elements and transient noise elsewhere in the system. Noise can manifest at the SMPS unit’s output as conducted and radiated noise. While diagnosing the cause of each problem can be challenging, these two types of noise can be easily distinguished.

Another design challenge in SMPS PCB layout is the heat generated on the board. While factors such as PWM frequency, duty cycle, and rise time influence this, effective thermal management strategies are still crucial. With these two challenges in mind, let’s examine some details to focus on in SMPS PCB layout.

**Thermal Management** An ideal SMPS would dissipate zero power, although this is not practical. Your switching transistors (and the input transformer for AC-DC conversion) will dissipate most of the heat. Even though switching power supply topologies can achieve 90% efficiency, power MOSFETs can still generate significant heat during switching. A common practice is to place heat sinks on critical switch components and ensure they are connected to the ground plane to avoid introducing new EMI. In high-voltage/high-current power supplies, these heat sinks can be quite large. To enhance cooling, consider installing fans in the chassis, but be sure to follow best practices for powering these fans to prevent new EMI issues.

**Some SMPS PCB Board Layout Tips** Your layout will contribute to thermal management to some extent, but it is a more significant factor in determining EMI susceptibility. Typically, conducted noise is managed using EMI filters on the input and output circuits. As with many EMI issues in high-speed/high-frequency systems, the stackup of your PCB is crucial in resisting radiated EMI. The relevant frequency range for SMPS operation is ~10 kHz to ~1 MHz, so radiated EMI will induce noise. Therefore, place the ground plane in the stackup directly below the surface layer, along with all power components, to ensure low loop inductance of the surface circuit. Any noise signal propagating to the output is usually filtered out at the output stage.

**Transient Ringing** Transients present a more challenging problem as they relate to your stackup, routing, vias, and decoupling/impedance issues. As with high-speed designs, avoid routing copper carrying switching signals across gaps in the ground plane, as this can create an antenna structure that radiates strongly during transients. These transients tend to be high-frequency (ranging from 10 to 100 MHz). The problem with transient ringing is primarily an impedance management issue. High impedance results in significant voltage ripple. Place components with the correct land pattern to minimize impedance in the board PDN. Examples of good and bad pads for your components are shown below.

**The Quality of the Components in the Layout** Generally, avoid isolated islands in your layout. Use decoupling capacitors to connect any power islands containing control circuitry or passive components back to the ground plane. Be cautious when placing vias on the PCB, as you want to avoid creating unintended gaps or sockets in the ground plane.