PCB and PCBA: The Backbone of Electronic Products

PCB: The “Mother” of Electronic Devices

Printed Circuit Board (PCB), also known as “印刷电路板” in Chinese, is a vital electronic component that provides structural support and electrical connections for electronic parts. PCBs are considered the foundation of electronic products due to their integration of electronics directly onto the board.

The Evolution from Wiring to PCBs

In the past, electronic components were interconnected through direct wiring. However, with the introduction of PCBs, wiring has become secondary, with printed circuit boards now dominating the electronics industry.

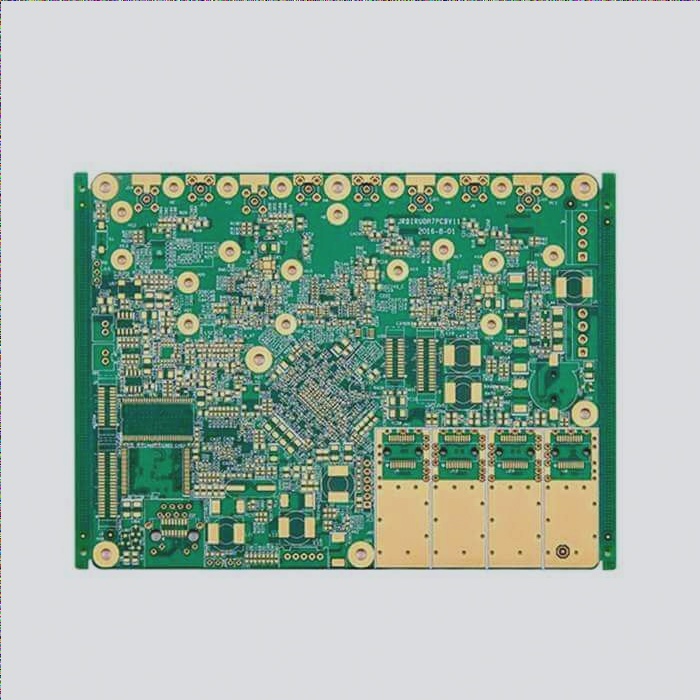

The PCB Production Process

- Drilling holes

- Creating copper patterns

- Transferring patterns

- Electroplating

- Thin film etching

- Applying green oil characters

- Gold-plating fingers

- Forming

Advantages of PCBs

- High density

- High reliability

- Design flexibility

- Productivity

- Testability

- Composability

- Maintainability

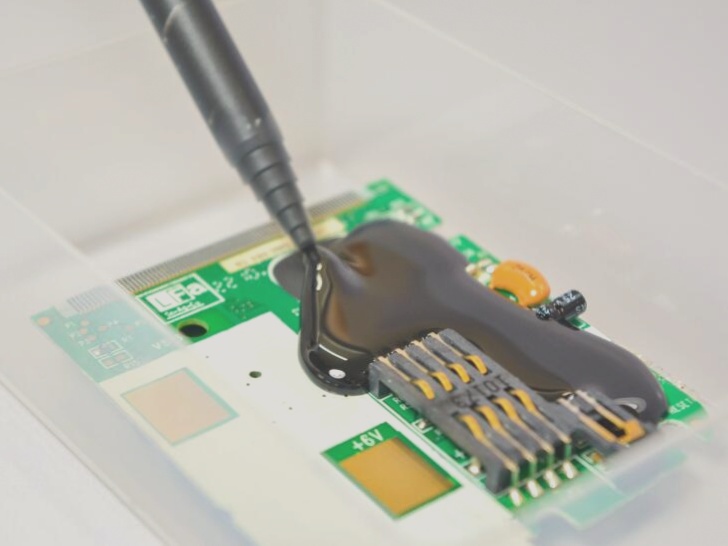

The Development of PCBA

PCBA (Printed Circuit Board Assembly) involves the assembly of empty PCB boards through methods like SMT or DIP plug-ins. It includes services for production, assembly, and technical support to meet diverse manufacturing needs.

SMT and DIP Processing

SMT (Surface-Mounted Technology) and DIP (Dual In-line Package) are methods used to integrate components onto PCBs. Shenzhen PCBA OEM primarily processes various electronic products using these methods.

Difference Between PCB and PCBA

PCBA represents a processed circuit board, considered a finished product. In contrast, PCB is an unpopulated board without components. PCBA is the final product, while PCB is the bare board.