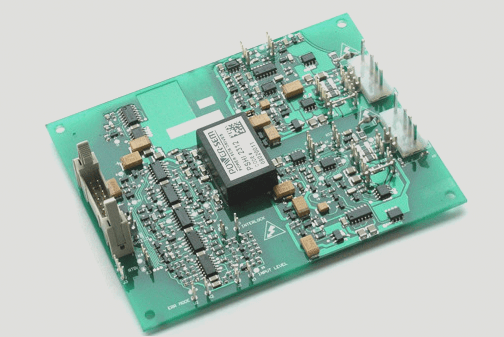

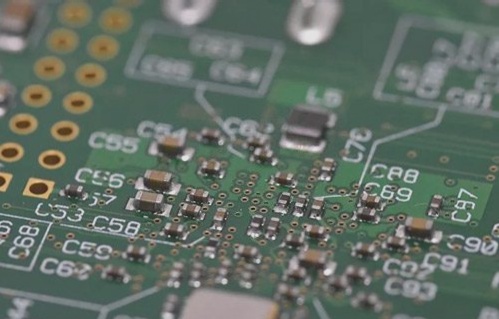

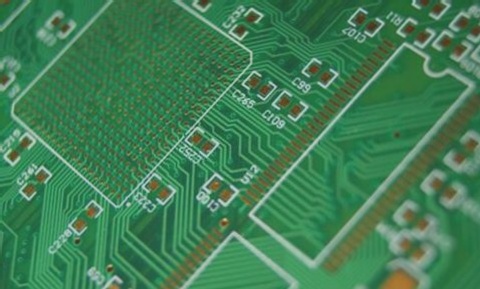

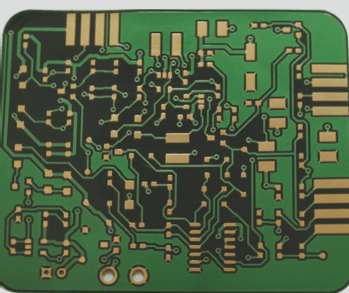

In the patch processing of electronic processing plants, the use of patch glue is a frequently used processing raw material. In actual production and processing, there are two main methods of using patch glue, manual and automatic. Generally, manual is used in small batch production. It is mainly used in high-volume SMT patch processing. The pressure injection method is divided into two ways: manual and automatic. Manual dispensing is the same as solder paste dispensing. It is used for testing or small batch production of PCBA. Automatic dispensing is used for medium and large batch production of PCBA. According to the difference of the distribution pump, it is divided into four types: time pressure, screw pump, piston pump, and spraying method.

Time pressure dispensing is a dispensing method characterized by time or pressure, and is the most primitive and widely used dispensing method. The working principle of the time pressure dispensing method is to use the pressure of compressed air to apply pressure to the adhesive and then dispense the adhesive through a needle valve. The advantages of the time pressure drop coating method in the actual production of SMT patch processing plants are good flexibility, convenient control, simple and reliable operation, easy cleaning of needles and needles, but there are also some disadvantages, such as the degree of viscosity is greatly affected, poor consistency at high speed and when dispensing small glue dots, etc., it needs to be selected and used according to the specific situation. There are also many parameters that affect the time pressure drop coating process, such as viscosity, pressure, time, temperature, inner diameter of the dispensing needle, and the stop height of the machine. Here are a few selected for a brief introduction.

1. The uniformity of viscosity dispensing is very sensitive to changes in the viscosity of the patch adhesive. The main factors affecting the viscosity of the patch adhesive are temperature and pressure.

2. Temperature will affect the viscosity and the shape of the glue point. As the temperature increases, the viscosity of the patch glue will decrease, which means that the amount of patch glue flowing out of the needle under the same time and pressure will increase.

3. The pressure is controlled within 5bar, usually between 3.0 and 3.5bar. Increase the pressure to increase the dispensing volume. In the analysis of objective reasons from a physical point of view, the above is an important reason that affects whether the pressure injection method can be implemented as scheduled, and it is also what the SMT small batch chip processing factory using the pressure injection method must understand.

Time pressure dispensing is a dispensing method characterized by time or pressure, and is the most primitive and widely used dispensing method. The working principle of the time pressure dispensing method is to use the pressure of compressed air to apply pressure to the adhesive and then dispense the adhesive through a needle valve. The advantages of the time pressure drop coating method in the actual production of SMT patch processing plants are good flexibility, convenient control, simple and reliable operation, easy cleaning of needles and needles, but there are also some disadvantages, such as the degree of viscosity is greatly affected, poor consistency at high speed and when dispensing small glue dots, etc., it needs to be selected and used according to the specific situation. There are also many parameters that affect the time pressure drop coating process, such as viscosity, pressure, time, temperature, inner diameter of the dispensing needle, and the stop height of the machine. Here are a few selected for a brief introduction.

1. The uniformity of viscosity dispensing is very sensitive to changes in the viscosity of the patch adhesive. The main factors affecting the viscosity of the patch adhesive are temperature and pressure.

2. Temperature will affect the viscosity and the shape of the glue point. As the temperature increases, the viscosity of the patch glue will decrease, which means that the amount of patch glue flowing out of the needle under the same time and pressure will increase.

3. The pressure is controlled within 5bar, usually between 3.0 and 3.5bar. Increase the pressure to increase the dispensing volume. In the analysis of objective reasons from a physical point of view, the above is an important reason that affects whether the pressure injection method can be implemented as scheduled, and it is also what the SMT small batch chip processing factory using the pressure injection method must understand.