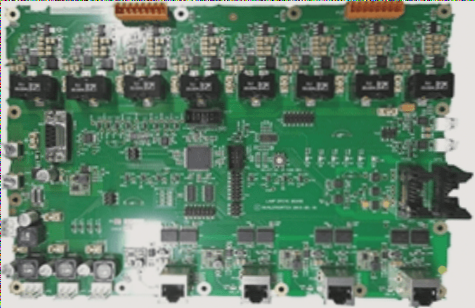

The Importance of SMT Patch Validation in PCB Manufacturing

Conducting a successful initial trial of Surface Mount Technology (SMT) patch validation is crucial for ensuring the accuracy and efficiency of mass production processes. By providing precise component specifications, models, and polarity directions during the first trial, manufacturers can prevent component misplacement and ensure correct alignment, leading to repeatability in mass production.

Methods for Conducting the Initial Trial

There are various methods available for conducting the initial trial of SMT patch validation, each tailored to meet the specific production needs of different PCB processing requirements.

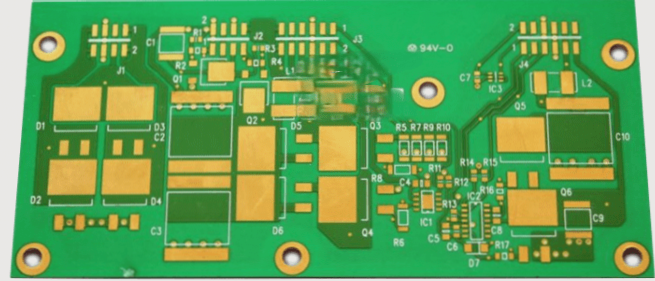

LCR Measurement Method

One effective method for the initial trial is the LCR measurement technique. This method is particularly suitable for relatively simple circuit boards with fewer components, as it eliminates the need for reflow post-printing completion, streamlining the validation process.