Loctite SMT Solder Paste

Applying solder paste is a crucial step in the SMT process, with metal stencil printing being the most prevalent method. This step is vital to ensuring SMT quality. Statistics show that, assuming PCB design specifications, components, and printed boards are correct, approximately 60% to 70% of quality issues arise during the printing process.

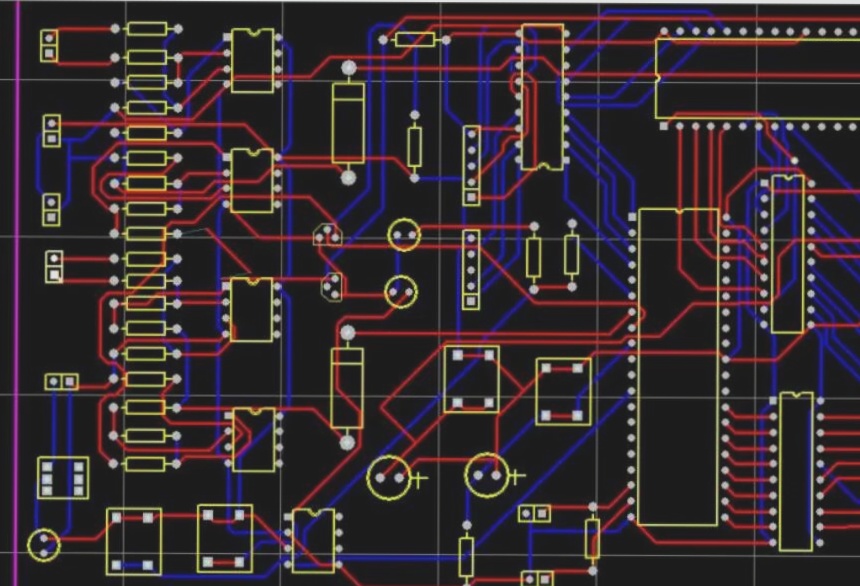

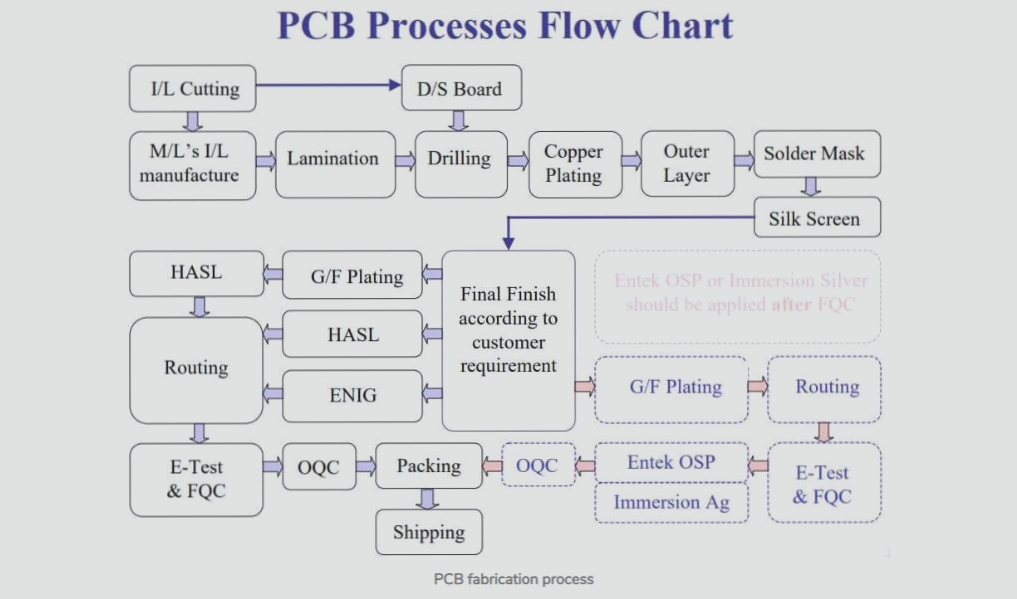

PCB Sinking Copper Production Line PCB Quality Inspection Brand Components

The requirements for printing solder paste are as follows:

1. The solder paste application must be uniform and consistent. The solder paste pattern should be clear, with adjacent patterns not fused together. The solder paste pattern must align with the pad pattern without misalignment.

2. Typically, the solder paste amount per unit area on the pad should be around 0.8 mg/mm²; for narrow-pitch components, it should be 0.5 mg/mm².

3. After printing, the solder paste should not exhibit significant collapse, the edges must be neat, and the substrate surface should remain uncontaminated by solder paste.

Solder Paste Reflow Profile

The physical, chemical, and process properties of solder paste have a direct impact on the quality of SMT soldering.

1. **Selection of Solder Paste**

There are many types and specifications of solder paste, and even among products from the same manufacturer, differences can exist in alloy composition, particle size, viscosity, and other factors. Choosing the solder paste that best suits your product greatly affects both quality and cost. Nuode Electronics Co., Ltd. currently uses Loctite lead-free solder paste. For this solder paste, we have conducted process experiments to test its printability, mold release, thixotropy, adhesion, wettability, solder joint defects, residues, and other characteristics. This solder paste is considered relatively advanced in terms of technology, ensuring effective PCBA quality control.

2. **Proper Use and Storage of Solder Paste**

Solder paste is a thixotropic fluid. Its printing performance, pattern quality, viscosity, and thixotropy are closely related. The viscosity of solder paste is influenced not only by the mass percentage of the alloy, the particle size, and the particle shape but also by temperature. Ambient temperature fluctuations can affect viscosity. Therefore, it is best to maintain the ambient temperature at 23°C ± 3°C. Since most solder paste printing is done in open air, ambient humidity also impacts solder paste quality; relative humidity should be kept between 45% and 70%. Additionally, the printing workshop should be clean, dust-free, and free from corrosive gases. With increasing assembly density and printing complexity, correct use and storage of solder paste are crucial. Key requirements include:

1) Storage at 2–10°C.

2) Remove solder paste from the refrigerator one day before use (at least 4 hours in advance) and allow it to reach room temperature before opening the container to prevent condensation.

3) Mix the solder paste evenly with a stainless steel mixing knife or automatic mixer before use. Stir in one direction if mixing manually. Mix for 3–5 minutes, whether by machine or manually.

4) After dispensing solder paste, ensure the container lid is closed.

5) Recycled solder paste should not be used for no-clean applications. If the printing interval exceeds 1 hour, wipe the solder paste off the stencil and return it to the container used on that day.

6) Perform reflow soldering within 4 hours after printing.

7) When repairing boards with no-clean solder paste, avoid using alcohol to clean solder joints if no flux is applied. If flux is used, remove any unheated residual flux from the solder joints, as unheated flux can be corrosive.

8) Products requiring cleaning should be cleaned within the same day after reflow soldering.

9) During solder paste printing and patch operations, hold the PCB by the edges or wear gloves to avoid contaminating the PCB.

3. **Inspection**

Printing solder paste is a critical process for ensuring the quality of SMT assembly, so it is essential to strictly control the quality of the printed solder paste. Inspection methods include visual inspection and SPI (Solder Paste Inspection) inspection. For visual inspection, use a magnifying glass with 2–5x magnification or a microscope with 3.5–20x magnification. SPI machines are used for inspecting narrow spacing. Inspection standards should adhere to IPC standards.

Applying solder paste is a crucial step in the SMT process, with metal stencil printing being the most prevalent method. This step is vital to ensuring SMT quality. Statistics show that, assuming PCB design specifications, components, and printed boards are correct, approximately 60% to 70% of quality issues arise during the printing process.

PCB Sinking Copper Production Line PCB Quality Inspection Brand Components

The requirements for printing solder paste are as follows:

1. The solder paste application must be uniform and consistent. The solder paste pattern should be clear, with adjacent patterns not fused together. The solder paste pattern must align with the pad pattern without misalignment.

2. Typically, the solder paste amount per unit area on the pad should be around 0.8 mg/mm²; for narrow-pitch components, it should be 0.5 mg/mm².

3. After printing, the solder paste should not exhibit significant collapse, the edges must be neat, and the substrate surface should remain uncontaminated by solder paste.

Solder Paste Reflow Profile

The physical, chemical, and process properties of solder paste have a direct impact on the quality of SMT soldering.

1. **Selection of Solder Paste**

There are many types and specifications of solder paste, and even among products from the same manufacturer, differences can exist in alloy composition, particle size, viscosity, and other factors. Choosing the solder paste that best suits your product greatly affects both quality and cost. Nuode Electronics Co., Ltd. currently uses Loctite lead-free solder paste. For this solder paste, we have conducted process experiments to test its printability, mold release, thixotropy, adhesion, wettability, solder joint defects, residues, and other characteristics. This solder paste is considered relatively advanced in terms of technology, ensuring effective PCBA quality control.

2. **Proper Use and Storage of Solder Paste**

Solder paste is a thixotropic fluid. Its printing performance, pattern quality, viscosity, and thixotropy are closely related. The viscosity of solder paste is influenced not only by the mass percentage of the alloy, the particle size, and the particle shape but also by temperature. Ambient temperature fluctuations can affect viscosity. Therefore, it is best to maintain the ambient temperature at 23°C ± 3°C. Since most solder paste printing is done in open air, ambient humidity also impacts solder paste quality; relative humidity should be kept between 45% and 70%. Additionally, the printing workshop should be clean, dust-free, and free from corrosive gases. With increasing assembly density and printing complexity, correct use and storage of solder paste are crucial. Key requirements include:

1) Storage at 2–10°C.

2) Remove solder paste from the refrigerator one day before use (at least 4 hours in advance) and allow it to reach room temperature before opening the container to prevent condensation.

3) Mix the solder paste evenly with a stainless steel mixing knife or automatic mixer before use. Stir in one direction if mixing manually. Mix for 3–5 minutes, whether by machine or manually.

4) After dispensing solder paste, ensure the container lid is closed.

5) Recycled solder paste should not be used for no-clean applications. If the printing interval exceeds 1 hour, wipe the solder paste off the stencil and return it to the container used on that day.

6) Perform reflow soldering within 4 hours after printing.

7) When repairing boards with no-clean solder paste, avoid using alcohol to clean solder joints if no flux is applied. If flux is used, remove any unheated residual flux from the solder joints, as unheated flux can be corrosive.

8) Products requiring cleaning should be cleaned within the same day after reflow soldering.

9) During solder paste printing and patch operations, hold the PCB by the edges or wear gloves to avoid contaminating the PCB.

3. **Inspection**

Printing solder paste is a critical process for ensuring the quality of SMT assembly, so it is essential to strictly control the quality of the printed solder paste. Inspection methods include visual inspection and SPI (Solder Paste Inspection) inspection. For visual inspection, use a magnifying glass with 2–5x magnification or a microscope with 3.5–20x magnification. SPI machines are used for inspecting narrow spacing. Inspection standards should adhere to IPC standards.