Soft and hard combined board is a new type of printed circuit board with durability and adaptability, which is used for three-dimensional assembly under different assemblies. It can be divided into two categories: soft and hard combined board and soft and hard combined board. The main difference lies in the material, structure, and some differences. The combination of soft and hard plates can effectively reduce the assembly size of electronic products, avoid online errors, realize light, intelligent, small volume, and strengthen the assembly flexibility. It is the main product of the electronic industry and has been widely used and valued.

The combination of soft and hard board was popular in Europe, America, Japan, and other developed countries at the beginning. After the reform and opening up, it also became popular in China. It is mainly used in consumer electronics, medical machinery, automobile electronics, precision instruments, aerospace, and other applications. Now the combination of hard and soft boards is not very perfect, there is still room for development in the market. The soft-hard combination board of deep connection circuit is mainly used in LED lighting, military aerial photography, smart home, medical products, wearable devices, high-frequency antenna boards, and other fields.

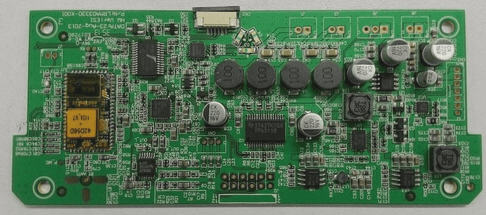

This eight-layer hard and soft plate is used for military aerial photography. The upper and lower structure design is asymmetric.

1. As a PCB expert, I specialize in medical products with six layers of hard and soft plate designs.

2. These PCBs are crucial components in various medical devices, ensuring the seamless functioning of equipment used in hospitals and healthcare facilities.

3. The six-layer design allows for a combination of rigid and flexible materials, providing the necessary support and adaptability for the specific requirements of medical equipment.

4. With my expertise, I ensure that these PCBs are manufactured to the highest standards, meeting the strict regulatory requirements for medical devices.

5. My attention to detail and precision in designing and fabricating these PCBs is essential to ensuring the reliability and safety of medical equipment used in the healthcare industry.

6. By providing reliable and high-quality PCBs for medical products, I contribute to the overall efficiency and effectiveness of medical treatment and care.

The combination of soft and hard board was popular in Europe, America, Japan, and other developed countries at the beginning. After the reform and opening up, it also became popular in China. It is mainly used in consumer electronics, medical machinery, automobile electronics, precision instruments, aerospace, and other applications. Now the combination of hard and soft boards is not very perfect, there is still room for development in the market. The soft-hard combination board of deep connection circuit is mainly used in LED lighting, military aerial photography, smart home, medical products, wearable devices, high-frequency antenna boards, and other fields.

This eight-layer hard and soft plate is used for military aerial photography. The upper and lower structure design is asymmetric.

1. As a PCB expert, I specialize in medical products with six layers of hard and soft plate designs.

2. These PCBs are crucial components in various medical devices, ensuring the seamless functioning of equipment used in hospitals and healthcare facilities.

3. The six-layer design allows for a combination of rigid and flexible materials, providing the necessary support and adaptability for the specific requirements of medical equipment.

4. With my expertise, I ensure that these PCBs are manufactured to the highest standards, meeting the strict regulatory requirements for medical devices.

5. My attention to detail and precision in designing and fabricating these PCBs is essential to ensuring the reliability and safety of medical equipment used in the healthcare industry.

6. By providing reliable and high-quality PCBs for medical products, I contribute to the overall efficiency and effectiveness of medical treatment and care.