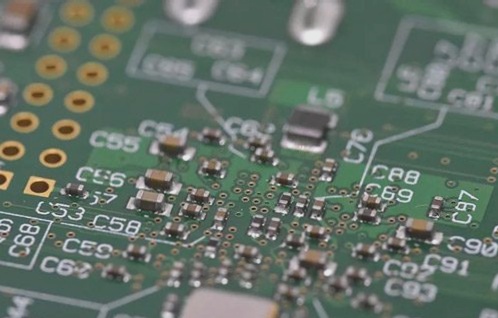

The Development Process in PCB Board Production

In the PCB board production process, the development stage plays a crucial role in creating precise and high-quality circuit boards. Here are the key steps involved in the development process:

1. Precise Control Parameters

- Temperature control of the developing solution

- Conveyor speed adjustment

- Spray pressure optimization

2. Developing Solution

The solder mask is removed from the pad using a 1% anhydrous sodium carbonate solution. The liquid temperature is maintained between 30 and 35 degrees Celsius for optimal results.

3. Three Stages of Development Machine

- Spraying: High-pressure injection of anhydrous sodium carbonate to dissolve the unexposed solder resist.

- Water Washing: Rinse residual solution with water and thorough washing with circulating water.

- Drying: Hot air from air machines used to dry the board, with higher temperatures expediting the process.

4. Importance of Development Time

Correct development time is crucial to prevent incomplete development or etching of the solder resist layer. Maintaining a consistent percentage within 40%-60% of the total length is essential for optimal results.

5. Precautions During Development

- Prevent board scratching by wearing gloves and handling boards gently.

- Arrange boards by size to avoid crowding during transmission.

- After development, place boards on wooden brackets for further processing.

By following these steps and precautions, the development stage in PCB board production can ensure the creation of high-quality circuit boards for various electronic applications.