The Importance of Size in Flexible Circuit Board (FCB) Layout

When designing flexible circuit boards (FCBs), the size of the board is a critical factor to consider. The size directly impacts various aspects of the PCB design and functionality. Here are some key considerations:

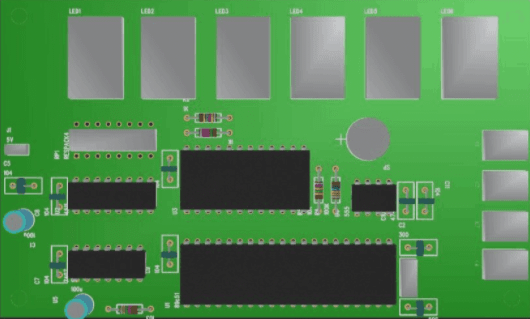

- Optimizing PCB Design: It is essential to find the right balance in size to ensure optimal performance. Too large of a board can lead to increased impedance and higher costs, while a board that is too small may result in challenges with heat dissipation and soldering control.

- EMI Interference: Minimize the wiring length between high-frequency components to reduce electromagnetic interference (EMI) and enhance the anti-noise capability of the board.

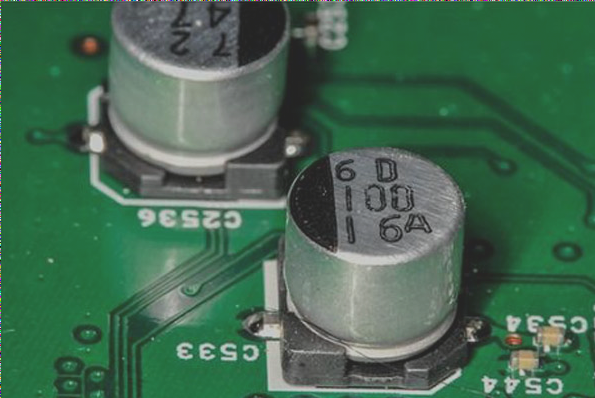

- Component Placement: Secure heavy-weight components with brackets before soldering to prevent issues. Address heat dissipation concerns for heated components to avoid defects and rework.

- Optimal Layout: Arrange components in parallel alignment for a clean appearance, easy soldering, and suitability for mass production. Maintain a 4:3 rectangular board shape for best performance and avoid altering wire widths to prevent discontinuities.

It is crucial to keep thermal components away from heat sources to maintain the board’s integrity. Additionally, prolonged heating of the board can cause copper foil swelling and detachment, so it’s important to avoid excessive use of copper foil areas.

WellCircuits Limited, a leading FPC manufacturer, has a strong track record of collaborating with esteemed clients. We are dedicated to assisting both existing and new customers with their PCB needs. If you have any inquiries or require assistance, please don’t hesitate to contact us.