Soldering Machines in Electronics Manufacturing

Introduction

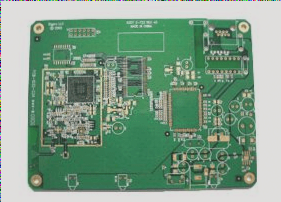

Soldering machines are crucial in the assembly of printed circuit boards (PCBs), ensuring reliable electrical connections between components. This article delves into the primary types of soldering machines and key considerations for their efficient operation.

Wave Soldering Machines

Wave soldering machines are commonly used for soldering through-hole components (THD) and certain surface-mount devices (SMD). They create a molten solder wave that the PCB passes over, enabling solder-component contact.

- Temperature Control: Maintaining the right soldering temperature is vital to prevent component and PCB damage.

- Flux Selection: Choosing suitable flux is crucial for high-quality solder joints, aiding in oxidation removal and solder wetting.

- Regular Maintenance: Periodic machine inspection and maintenance ensure consistent performance and prevent issues.

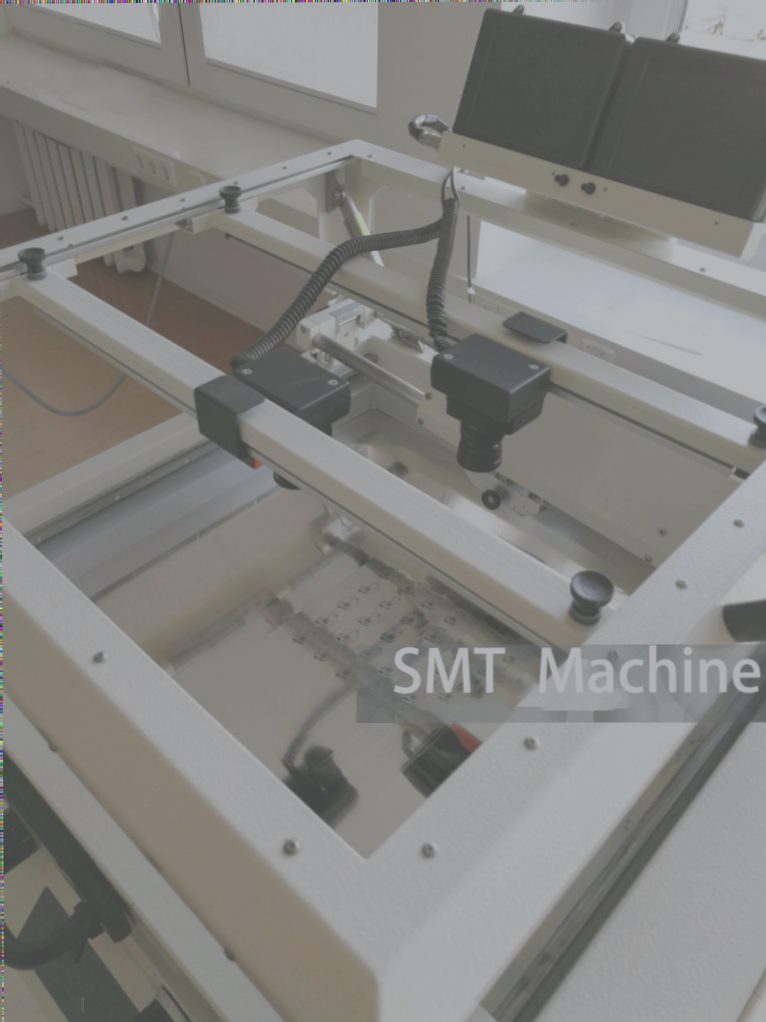

Reflow Soldering Machines

Reflow soldering machines are primarily for soldering surface mount devices (SMDs), involving stages like preheating, reflowing, and cooling for strong solder joints.

- Solder Paste Application: Uniform paste application is essential to avoid solder joint defects.

- Temperature Profile: Calibrating temperature sensors ensures accurate heating profiles, crucial for solder quality.

- Atmospheric Control: Monitoring the atmosphere during reflow prevents oxidation, enhancing solder joint durability.

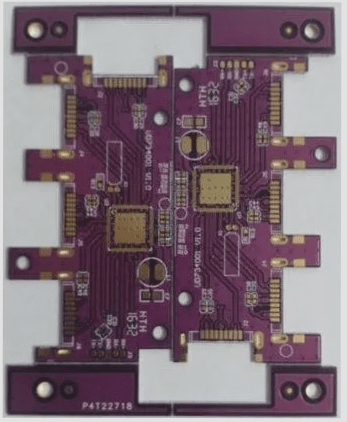

Selective Soldering Machines

Selective soldering machines target specific PCB areas, ideal for mixed technology applications involving THDs and SMDs.

- Surface Cleanliness: Contaminant-free surfaces are vital for strong solder joints and reliability.

- Nozzle Maintenance: Regular nozzle upkeep prevents clogs that can impact solder application precision.

Soldering Machine Efficiency

Efficient soldering machine operation relies on temperature control, flux selection, regular maintenance, uniform paste application, accurate temperature profiles, atmospheric control, surface cleanliness, and proper nozzle maintenance. By adhering to these practices, manufacturers ensure high-quality, reliable solder joints, leading to superior electronic device performance.

Proper Soldering Techniques for High-Quality PCB Assembly

Before beginning the soldering process, it is crucial to ensure that the solder temperature is set correctly. Incorrect temperature settings can lead to damaged components or poor solder joints. Maintaining the proper soldering temperature is essential for creating reliable connections.

Reflow and Selective Soldering Processes

Reflow and selective soldering are vital processes in modern PCB assembly. Reflow soldering requires consistent solder paste application, accurate temperature monitoring, and oxidation prevention. On the other hand, selective soldering demands surface cleanliness, proper nozzle maintenance, and correct soldering temperatures for optimal results.

Manual Soldering Stations

- Manual soldering stations are ideal for low-volume production and prototyping purposes.

- Operators use soldering irons or guns for intricate, high-precision work on PCBs.

Key Factors for Effective Soldering

- Ensure correct temperature and power settings on soldering tools.

- Provide operators with proper training in soldering techniques.

- Maintain tools regularly to prevent issues like poor heat transfer.

Soldering Machines in Electronics Manufacturing

Various soldering machines, including wave, reflow, and selective soldering, offer unique advantages and challenges in electronics manufacturing. Each method caters to different production needs and requirements.

Impact of Soldering Technology on Product Quality

With the trend toward smaller and more integrated electronic products, the choice of soldering technology significantly impacts product quality and reliability. Precise soldering methods are essential to meet the demands of compact components and tight tolerances.

Conclusion

Manufacturers must understand different soldering machines and operational considerations to remain competitive in the evolving electronics market. By selecting the right soldering technology, providing adequate training, maintaining tools, and controlling processes, manufacturers can ensure high-quality production and reliable electronic products.