SMD Component Mounting Solutions on FPC Boards

Commonly Used Methods:

- Multi-chip Placement:

- Component Types: Suitable for chip components larger than 0603 and QFP components with pin spacings of 0.65mm or greater.

- Number of Components: Ranges from a few to more than a dozen per FPC.

- Mounting Accuracy: Moderate accuracy required.

- FPC Characteristics: FPCs are larger in area, have designated component-free zones, and feature MARK marks for optical positioning and positioning holes.

- High-precision Mounting:

- Component Types: Suitable for all conventional components, including QFPs with pin spacing less than 0.65mm.

- Number of Components: Suitable for dozens or more components.

- Mounting Accuracy: Ensures high precision placement accuracy of QFPs at 0.5mm.

- FPC Characteristics: Large areas, multiple positioning holes, and optical positioning marks for critical components.

Additional Information:

FPCs and plastic-encapsulated SMD components are considered “moisture-sensitive devices.” To prevent warping and delamination, store FPCs in moisture-proof conditions and dry them before use. Large-scale production often involves high-temperature drying methods.

For the preservation of solder paste, store it in a low-temperature environment and allow it to return to room temperature before use. Avoid rapid reheating and ensure thorough stirring for optimal printing results.

Maintain an ambient temperature around 20°C with relative humidity below 60% for solder paste printing. Use a relatively closed space to minimize air convection.

When using metal bushings, ensure the thickness is between 0.1mm-0.5mm for effective solder paste stripping. Precision methods like chemical corrosion, laser, or electroforming are recommended for optimal results.

Solder Paste Selection for SMD Placement on Flexible Printed Circuits (FPCs)

- Particle Shape and Diameter: Opt for spherical solder paste with a diameter less than one-third of the metal bushing thickness and one-fifth of the aperture width. Aim for particles around 40um to prevent blockages and ensure high printing quality.

- Solder Ratio: Choose a solder paste with 90%-92% solder content for moderate viscosity, preventing sagging during printing and ensuring strong welds post-reflow.

- Viscosity: Ideal solder paste viscosity ranges from 700-900Kcps. Low viscosity can lead to short circuits, while high viscosity may block metal leak holes.

- Thixotropic Coefficient: Aim for a coefficient between 0.45-0.60.

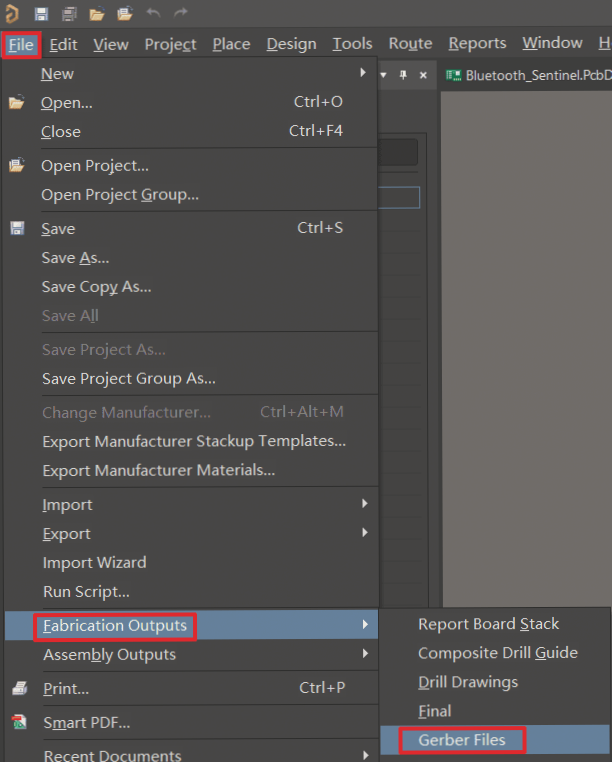

Printing Parameters for FPC SMD Placement

- Squeegee Type and Hardness: Utilize a polyurethane flat scraper with 80-90 degrees hardness for the uneven surface of FPCs.

- Scraper Angle: Maintain a scraper angle between 60-75 degrees.

- Printing Direction: Opt for left-right or front-rear printing, angled for effective paste application on all QFP pad sides.

- Printing Speed: Set printing speed between 10-25mm/s to prevent squeegee issues.

- Printing Pressure: Adjust pressure from 0.1-0.3kg/cm length for proper solder paste application.

- Stripping Speed: Choose a stripping speed of 0.1-0.2mm/s for effective paste release.

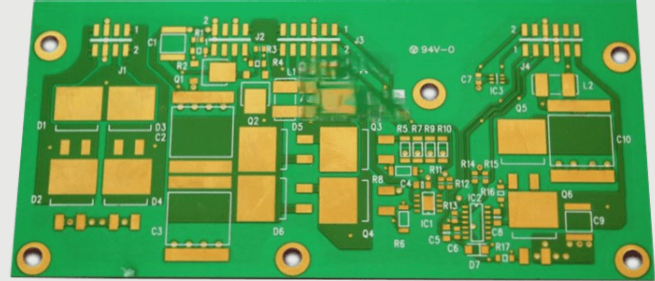

Mounting and Reflow Soldering Tips

- Mounting: Use medium to high-speed placement machines and pay attention to suction force in the nozzle to avoid placement problems.

- Reflow Soldering: Opt for forced hot air convection infrared reflow soldering for even temperature changes and reduced soldering defects.

- Temperature Curve Test Method: Conduct temperature curve tests with FPC pallets to ensure proper component attachment.

- Temperature Curve Setting: Control reflow soldering time to about 3 minutes and adjust heating speeds based on solder paste characteristics.

Summary: Proper fixation and precise process parameter adjustments are key to maintaining high-quality SMD placement on FPCs. Focus on solder paste selection, printing, and reflow parameters to minimize defects in SMT production.

العربية

العربية 简体中文

简体中文 Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 한국어

한국어 Português

Português Русский

Русский Español

Español ไทย

ไทย