The Growing Importance of Automotive Electronic PCB Processing in the Era of Ecological Civilization

In today’s rapidly evolving society, the construction of ecological civilization and the protection of the environment have taken center stage. Recognizing the direct impact of the ecological environment on social well-being and the importance of sustainable practices for future generations, the focus on environmental protection measures has intensified.

Driving Forces of Change

- The Shift to Autonomous Driving and New Energy Vehicles

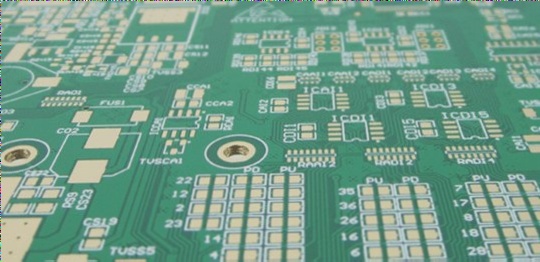

The rise of autonomous driving technology and the increasing adoption of new energy vehicles have led to a surge in demand for automotive printed circuit boards (PCBs). Companies like Tesla, BYD, and NIO are driving this trend, boosting orders for PCBA processing manufacturers. The stringent reliability requirements for automotive PCB processing have raised the industry’s threshold, resulting in substantial profit margins.

Key Growth Areas

- Expansion in Automotive PCB Usage

The transition to autonomous and new energy vehicles has fueled the demand for automotive PCB electronic control boards. As technology advances, the integration of automotive intelligent systems is expected to deepen, driving further growth in the sector.

- Rise of Millimeter Wave Radar Technology

The rapid development of millimeter-wave radar, especially in bicycles, is increasing the demand for high-frequency PCB circuit boards. This trend is set to enhance the value proposition of PCBA processing and manufacturing, with radar PCBs playing a crucial role in the industry.

- Advancements in New Energy Vehicle Power Battery BMS Technology

The Battery Management System (BMS) in new energy vehicles is poised for significant upgrades, offering optimization of battery performance and enhanced safety features. The growth of BMS technology will drive demand for PCB circuit board components, presenting lucrative opportunities in the market.

- Challenges and Opportunities in Automotive PCB Processing

The automotive PCB sector presents high entry barriers, favoring established PCBA manufacturers with proven track records. With stringent quality standards and environmental resilience requirements, the industry demands top-tier reliability and performance. Leading companies enjoy stable long-term orders and growth potential, underscoring the advantages of expertise and experience in the field.