Protect Your PCBs with Three-Proof Paint

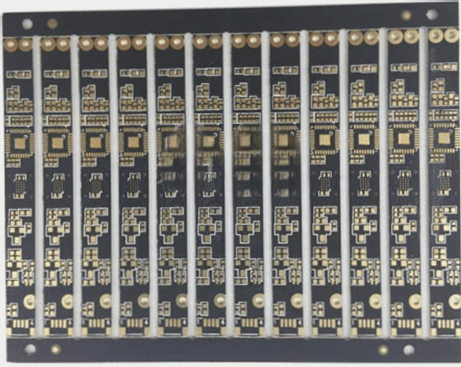

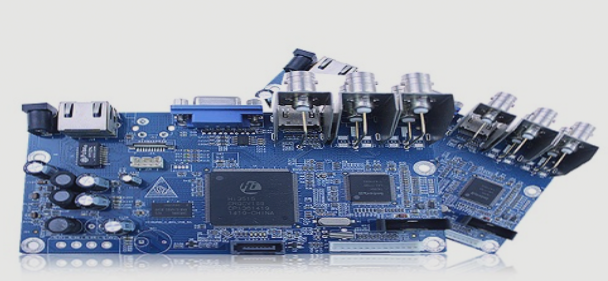

Three-proof paint is a specialized coating that provides essential protection for PCB circuit boards and related equipment against environmental damage. This unique paint offers exceptional resistance to extreme temperatures, moisture, corrosion, and more, ensuring the longevity and reliability of your circuits.

Benefits of Three-Proof Paint:

- Outstanding insulation

- Moisture resistance

- Leakage protection

- Shock resistance

- Dust resistance

- Corrosion resistance

- Aging resistance

- Corona resistance

Without proper protection, circuit boards can suffer from corrosion, mold growth, and malfunctions when exposed to chemicals, vibrations, humidity, and extreme temperatures. By applying three-proof paint, you can shield your circuits effectively and enhance their reliability, safety, and lifespan.

Moreover, the use of three-proof paint allows for higher power utilization and closer spacing between printed boards, facilitating component miniaturization and optimizing circuit performance.

Specifications and Requirements of Three-Proof Paint Process

Painting Requirements:

- Spray Paint Thickness: Maintain a film thickness of 0.05mm to 0.15mm.

- Secondary Coating: Apply a secondary coating for products with high protection needs.

- Inspection and Repair: Ensure quality standards are met through visual inspection and repair of any issues.

- PCB Component Replacement: Follow specific steps for component replacement after curing.

Operation Requirements:

- Workspaces must be clean and well-ventilated.

- Wear protective gear to prevent personal injury.

- Clean tools promptly and store paint securely.

- Implement anti-static measures and avoid stacking circuit boards during coating.

Quality Requirements:

- Avoid paint drips and ensure a smooth, glossy paint layer.

- Check for defects like bubbles, pinholes, or dust.

- Avoid touching the paint film before it dries.

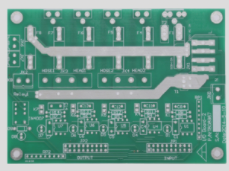

Parts and Devices Not Suitable for Three-Proof Paint

Some components, such as high-power radiators, resistors, diodes, and various connectors, are not compatible with three-proof paint. It is essential to identify and exclude these parts from the coating process to prevent damage or malfunction.

Guidelines for Three-Proof Paint Application on PCBAs

- Devices listed in the “Non-Three-proof Components (Area) Catalogue” should not be coated with three-proof paint.

- If non-coatable devices need coating, follow specifications from the R&D department or drawings.

Precautions for Three-Proof Paint Spraying

- PCBA must have a crafted edge, at least 5mm wide for machine tracking.

- Maximum PCBA dimensions: 410mm x 410mm; minimum dimensions: 10mm x 10mm.

- Maximum height of mounted PCBA components should not surpass 80mm.

- Maintain a minimum 3mm distance between sprayed and non-sprayed component areas on the PCBA.

- Thoroughly clean to remove corrosive residues for better three-proof paint adhesion.

- Recommended paint thickness: 0.1mm to 0.3mm; bake at 60°C for 10-20 minutes.

- Avoid spraying certain components like high-power radiating surfaces and power resistors.

PCB Tri-Proof Paint Rework Overview

When repairing a circuit board, costly components may be removed individually, while others can be discarded. Alternatively, remove the protective film from the board, replace damaged components, and ensure the substrate and nearby structures are unharmed. Methods include chemical solvents, micro-grinding, mechanical means, and desoldering through the film. Chemical solvents rely on film compatibility, micro-grinding uses high-speed particles, mechanical methods are direct, while desoldering needs a drain hole for molten solder escape.