The Importance of Silkscreen Layer in PCB Design

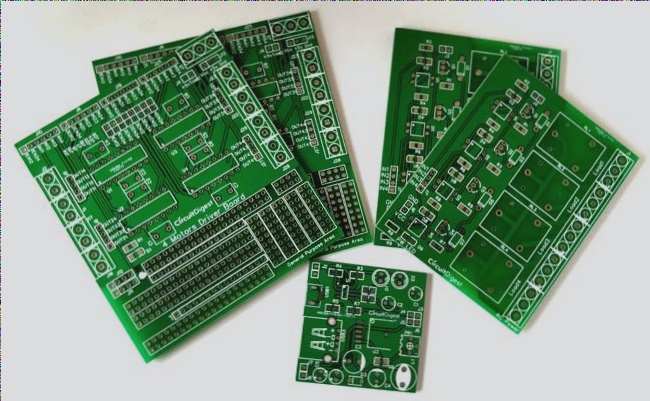

The silkscreen layer of a PCB board plays a vital role in guiding circuit installation and maintenance by providing essential information through logos, patterns, and text codes on the board’s surfaces.

Key Guidelines for Silkscreen Placement:

- Components should be placed in only two directions to avoid visual fatigue.

- Avoid placing vias on the silkscreen whenever possible.

- Avoid pressing silkscreen on high-speed signal lines to maintain signal quality.

- Ensure consistent reading direction for easy soldering and component identification.

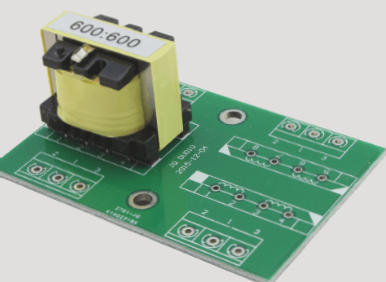

- Clearly mark pin numbers and connectors for easy assembly.

- Match silkscreen size with specially packaged components for alignment.

- Add markings near mounting holes for easy installation.

- Address ambiguity with clear markings like signal flow directions.

Best Practices for Silkscreen Layout:

- Label all components and holes clearly for easy identification.

- Avoid placing silkscreen on solder pads or tin baths.

- Mark polarity of components for quick reference.

- Ensure accuracy of PCB photo files and component identifiers.

- Indicate directional connectors clearly.

- Include barcode and essential information on the PCB documents.

Following these guidelines ensures that the silkscreen layer on a PCB board is optimized for functionality, clarity, and ease of use during the circuit’s lifecycle.