Standard PCB Thickness Guide

Printed Circuit Boards (PCBs) serve as the foundation for most electronic devices. They are relatively simple in structure, typically consisting of a single layer. While PCBs are commonly associated with computer hardware, they are also integral components in radios, televisions, cell phones, and more. The performance of a PCB is influenced by various factors, including the materials used in manufacturing, cost considerations, prototyping, and fabrication methods.

Moreover, the thickness of a PCB plays a crucial role in its overall performance and durability. It impacts the board’s resistance and conductivity, making it essential to determine the ideal thickness. When we refer to a “standard” feature or measurement for PCBs, we aim to achieve an optimal attribute that ensures our product excels in performance, weight, durability, reliability, and quality. The introduction of Aluminum as a material for PCB manufacturing has enhanced accessibility, affordability, and efficiency, moving beyond the traditional use of copper foils.

There is no universally defined standard thickness for PCB sheets; instead, market preferences dictate commonly used thicknesses. Achieving varied thicknesses involves combining prepreg sheets and core materials of different thicknesses. The market offers a range of PCB thickness options to cater to diverse needs.

What is the Standard PCB Thickness?

The current standard PCB thickness typically falls within the ranges of 0.031in (0.78mm), 0.062in (1.57mm), and 0.093in (2.36mm). However, the most frequently utilized thickness is 0.063in (1.57mm). It’s important to note that user requirements and specific applications also influence PCB thickness standards. Historically, plywood was a common substrate material, resulting in thicker boards. Advancements have introduced superior alternatives like epoxy for enhanced performance.

PCB Copper Thickness

Copper stands out as the predominant metal in PCB functionality and application due to its smoothness in achieving standard board thickness, typically around an ounce (oz). Thinner PCBs may limit surface finish options available due to copper’s properties.

Several manufacturing and design aspects impact PCB thickness, including:

The Design Factors Influencing PCB Thickness

- PCB size

- Number of layers

- Yield

PCB Complexity:

- Number of layers

Factors to Consider for PCB Thickness

- Number of vias

When selecting materials for your PCB, consider factors such as:

- Operational speed

- Frequency

- Operating temperature (Max.)

Factors affecting PCB thickness due to manufacturing processes:

- Size and number of holes

- Copper Thickness

- Tolerance

- Surface Finish

- Depanelization method

- Gap and track geometry

When determining the PCB thickness, trace width calculators play a crucial role. These calculators provide precise measurements, ensuring the board’s durability and performance. Keep in mind factors like weight, flexibility, impedance matching, required space, connection, component compatibility, and design requirements for optimal thickness selection.

Custom PCB Thickness Options

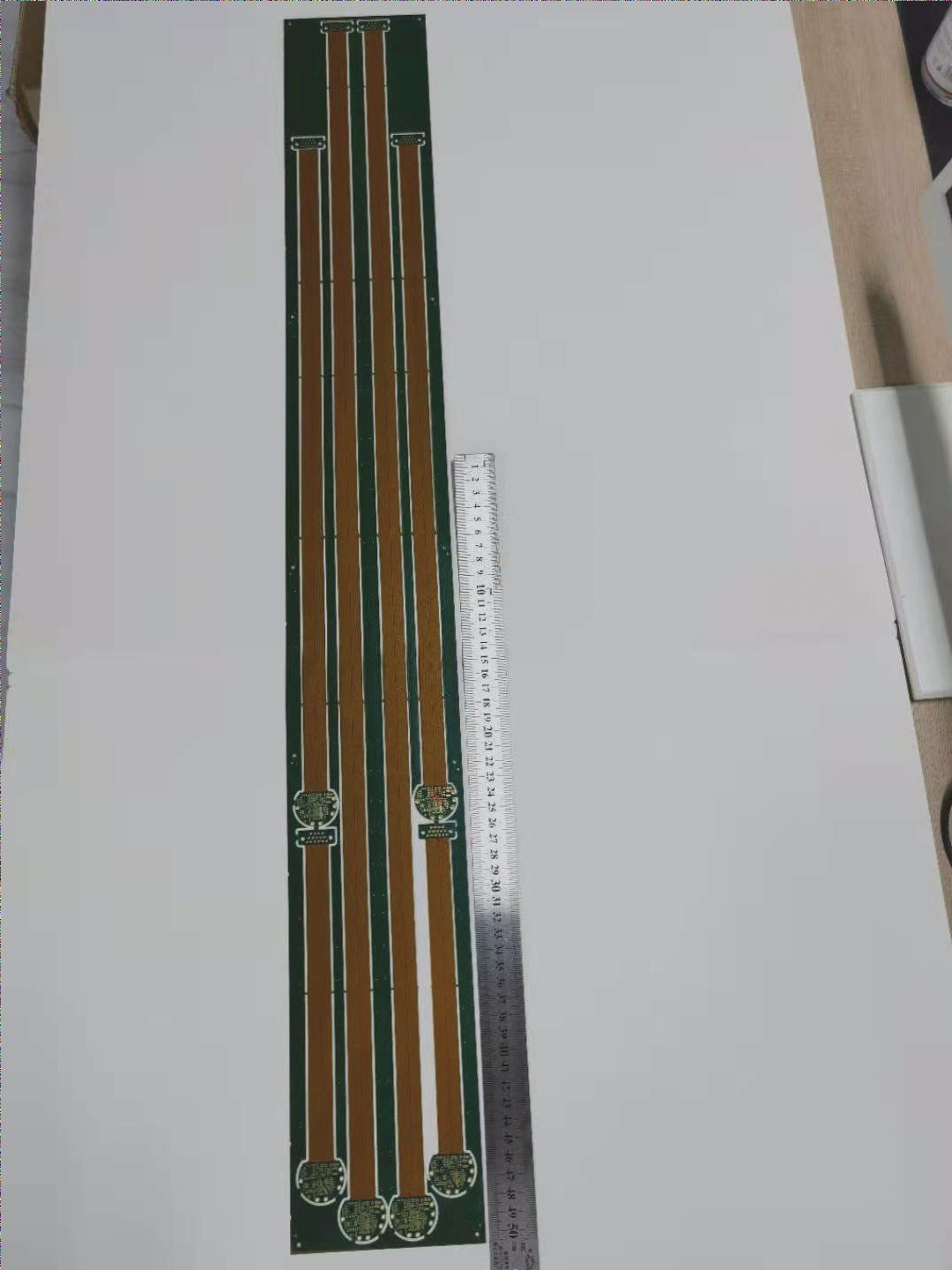

Customized PCB thicknesses ranging from 0.2mm to 6.3mm are readily available in the market. Various customization options cater to specific design needs. Consider these factors when opting for a custom PCB thickness.

Custom PCB Manufacturing Considerations

- Turnaround Time: Customized PCB layer thickness may result in longer turnaround times, affecting delivery schedules and development timing.

- CM’s Equipment Capabilities: Choose a CM with adequate equipment options to avoid compromising your design. Limited options may require modifications to your PCB layout.

- Additional Costs: Customization often incurs higher costs due to specific materials and detailed instructions, leading to increased manufacturing expenses.

Customizing thickness can enhance design appeal and performance but using multiple layers can be costly due to extra processing steps and materials involved.

Partnering with a reliable manufacturer is crucial for achieving the desired thickness seamlessly. The customization process typically involves combining core prepreg thickness with copper plating, copper foil, and solder mask.

At WellCircuits Electronics, we prioritize high-quality, accurate prototypes to meet all standard and customization needs. Our Custom PCB Manufacturing Service features:

- Accurate quote within 24 hours

- Turnkey process completed within or less than three days

- Reduced procurement time

- Dedicated Quality Certification

- High PCB quality

- Automated Optical Inspection

Experience our efficient service by requesting a quotation at sales@wellcircuits.com. We ensure prompt delivery of quality-manufactured designs. Quality is our top priority.

Click here to securely send your files to us for fast processing!