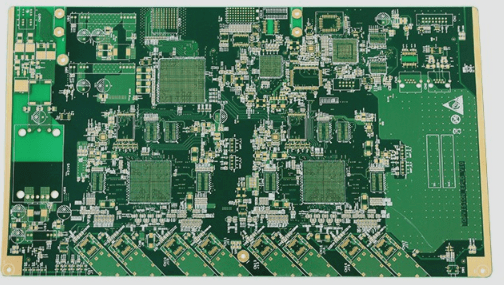

PCBA Surface Treatment Process

When it comes to PCB assembly, surface treatment is a crucial step to ensure the quality of the final product. After drilling the PCBA, it is common to find residual copper foil burrs around the through holes. These burrs not only create a rough texture but can also impact plating quality. Here is a simple guide on how to effectively treat the PCBA surface:

- Use 400-grit sandpaper or steel wool to gently scrub the PCBA surface until it is smooth to the touch.

- Inspect the PCBA under a light source to identify any blockages in the holes. If blockages are found, use compressed air to blow out the debris. This helps prevent obstructions and ensures proper conductivity post-electroplating. In the absence of compressed air, a drill bit smaller than the hole diameter can be utilized to remove debris.

Silver Glue Through Hole

Another important aspect of PCB assembly is the use of silver glue through holes. This process enhances the conductivity and reliability of the circuit board. Silver glue is applied to the through-holes to create a strong connection and improve overall performance.