Could you specify if you’re looking for improvements in clarity, technical accuracy, or both?

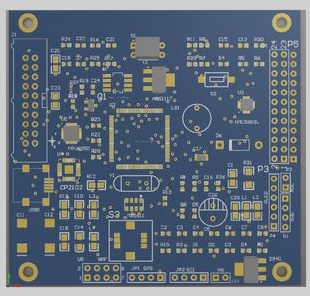

1. High assembly density, small size, and light weight characterize modern electronic products. The volume and weight of SMD components are approximately 1/10 that of traditional through-hole components. Generally, after adopting SMT, the volume of electronic products is reduced by 40% to 60%, and the weight is reduced by 60% to 80%.

2. High reliability and strong anti-vibration ability are key benefits. The defect rate of solder joints is notably low, and SMD components offer excellent high-frequency characteristics. They help reduce electromagnetic and radio frequency interference.

3. SMT facilitates automation and enhances production efficiency, leading to a cost reduction of 30% to 50%. This process conserves materials, energy, equipment, manpower, and time.

4. Electronic products are increasingly pursuing miniaturization, rendering traditional through-hole components obsolete. Modern electronic products have more comprehensive functions, utilizing integrated circuits (ICs) without through-hole components. Especially large-scale and highly integrated ICs necessitate the use of surface mount components.

5. With the shift towards mass production and automation, factories must focus on producing high-quality products at low costs and high outputs to meet customer demands and strengthen market competitiveness. The evolution of electronic components, integrated circuits (ICs), and the extensive applications of semiconductor materials are driving this transformation. The advancement of electronic technology is essential to stay aligned with international trends.

6. In practice, the environmental requirements of the production workshop are relatively stringent during Wuxi SMD processing. Factors such as temperature, humidity, and cleanliness significantly impact product quality. After chip processing, component volume can be effectively reduced by 40% to 60%, and weight can be decreased by 60% to 80%, resulting in substantial material and energy savings.

7. As social science and technology advance, automation levels continue to rise. Patch processing enhances the automation of products and production, thereby contributing significantly to the PCB industry’s progress.

1. High assembly density, small size, and light weight characterize modern electronic products. The volume and weight of SMD components are approximately 1/10 that of traditional through-hole components. Generally, after adopting SMT, the volume of electronic products is reduced by 40% to 60%, and the weight is reduced by 60% to 80%.

2. High reliability and strong anti-vibration ability are key benefits. The defect rate of solder joints is notably low, and SMD components offer excellent high-frequency characteristics. They help reduce electromagnetic and radio frequency interference.

3. SMT facilitates automation and enhances production efficiency, leading to a cost reduction of 30% to 50%. This process conserves materials, energy, equipment, manpower, and time.

4. Electronic products are increasingly pursuing miniaturization, rendering traditional through-hole components obsolete. Modern electronic products have more comprehensive functions, utilizing integrated circuits (ICs) without through-hole components. Especially large-scale and highly integrated ICs necessitate the use of surface mount components.

5. With the shift towards mass production and automation, factories must focus on producing high-quality products at low costs and high outputs to meet customer demands and strengthen market competitiveness. The evolution of electronic components, integrated circuits (ICs), and the extensive applications of semiconductor materials are driving this transformation. The advancement of electronic technology is essential to stay aligned with international trends.

6. In practice, the environmental requirements of the production workshop are relatively stringent during Wuxi SMD processing. Factors such as temperature, humidity, and cleanliness significantly impact product quality. After chip processing, component volume can be effectively reduced by 40% to 60%, and weight can be decreased by 60% to 80%, resulting in substantial material and energy savings.

7. As social science and technology advance, automation levels continue to rise. Patch processing enhances the automation of products and production, thereby contributing significantly to the PCB industry’s progress.