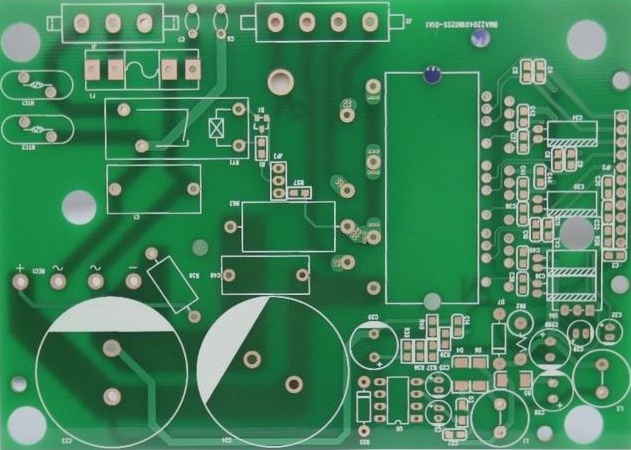

The Importance of PCB Board System Interconnections

PCB board systems rely on various connections, including linking chips to the circuit board, internal interconnections, and connections with external devices. In RF design, engineers face challenges with electromagnetic characteristics at connection points. To address this, different techniques are used, such as device mounting methods, wiring isolation, and lead inductance reduction.

Increasing Frequency in PCB Designs

The frequency of printed circuit board designs is on the rise, driven by increasing data rates that require higher signal frequencies, reaching 1 GHz and beyond. This technology covers not only mmWave (30 GHz) but also RF and low-end microwave technologies.

Challenges in RF Engineering

RF engineering must manage strong electromagnetic field effects at higher frequencies, which can induce unwanted signals and crosstalk on PCB traces, affecting system performance. Return loss, often due to impedance mismatches, can degrade signal quality and add noise to the system, impacting receiver performance.

Design Goals for PCB Boards

The aim of PCB board design is to be compact, fast, and cost-effective. In RF PCBs, high-speed signals can limit miniaturization. Strategies to combat crosstalk issues include ground plane management, trace spacing, and stud capacitance reduction. Impedance matching is crucial to minimize return loss, requiring effective material management and signal line isolation.

Interconnection Point Focus

As the weakest link in the circuit chain, the interconnection point in RF design demands thorough examination to address electromagnetic properties effectively. Each interconnection type—chip-to-board, internal PCB interconnections, and signal I/O with external devices—needs careful consideration for optimal system performance.

High-Frequency PCB Design Challenges and Solutions

Modern high-speed chips, like the Pentium IV, boast numerous I/O interconnect points and impressive processing rates of up to 1GHz. As the industry grapples with managing the growing number and frequency of I/Os, a key hurdle in chip-to-PCB interconnection emerges: high interconnection density.

An innovative approach proposes the use of local wireless transmitters within chips to relay data to nearby circuit boards. While the efficacy of this method is under scrutiny, it underscores the evolution of IC design techniques beyond traditional PCB methods for high-frequency applications.

Key Strategies for High-Frequency PCB Design

- Utilize a 45° corner of transmission lines to minimize return loss

- Employ high-performance insulating materials with controlled insulation constants

- Enhance PCB design specifications for precise etching

- Avoid tap inductance in protruding leads by utilizing surface mount components

- Strategically layout signal vias to mitigate lead inductance

- Establish a robust ground plane interconnected with molded holes

- Implement electroless nickel or immersion gold plating processes

- Incorporate solder mask for efficient solder paste management

For those unversed in these techniques, seeking counsel from seasoned design engineers, especially those versed in military microwave circuit boards, can offer valuable insights. These experts can provide guidance on cost-effective design approaches and address signal input/output challenges between PCBs and external devices.

Companies like Trompeter Electronics, renowned for their innovative coaxial cable technology, are pioneering solutions to manage transitions between microstrip and coaxial cable designs. Ground plane management remains critical for optimal signal transmission in both coaxial cables and microstrip configurations.