**PCB Assembly and SMT Chip Processing**

1. High costs are a common challenge faced by many industries, and regardless of how the economy improves, numerous American businesses are continuously seeking effective ways to lower costs and improve profit margins, all while maintaining product quality and process development. This is especially true in the electronics industry.

2. One of the most pressing issues for electronics manufacturers and original equipment manufacturers (OEMs) is the rapidly evolving technology, which demands increasingly complex PCB assembly services. To address these challenges, it is essential to uphold quality standards throughout every stage of PCB assembly.

3. Naturally, there is a need to consider strategies for reducing PCB assembly costs without compromising quality. The goal is to streamline the process, simplifying wherever possible, and minimizing PCBA costs as effectively as possible. This is not about overcomplicating the process to make it more compact, versatile, or reliable, but rather finding straightforward solutions to lower expenses.

4. For most electronics manufacturers, identifying the key areas where costs can be safely reduced—while still meeting customer expectations for high-quality products—is not an easy task.

Here is a slightly refined version of your text with improved phrasing, while keeping the meaning, clarity, technical accuracy, and style intact:

—

1. At the same time, balancing project schedules and budgets remains a challenge. On one hand, strict inspection procedures lead to higher costs. On the other hand, neglecting or skipping these inspections in the PCB assembly process can result in even higher costs. So, why not explore simple methods and strategies to achieve greater cost savings?

2. Minimize complexity by offering a range of design options, which can help ensure that the correct prototype is selected from the outset. Streamline the design by applying common structural elements to reduce costs. Complex shapes often result in increased manufacturing expenses.

3. A well-planned and efficient PCB layout is crucial. An essential phase in PCB assembly is the “stealing” process, which requires careful planning to minimize costs. This phase involves the PCB layout design. Through strategic PCB engineering, you can optimize the use of high-quality components, which can significantly reduce the cost per PCB.

4. Allocate sufficient time to create a well-organized and detailed bill of materials (BOM). A complete BOM should include all the essential information, such as reference designators, part numbers, specifications, quality requirements, SMT assembly methods, manufacturer names, component footprints, packaging details, and BOM levels. Most importantly, include component substitutions in the BOM. Given the rapid pace of technological advancements, it’s crucial to replace outdated components with newer alternatives to keep pace with the competitive PCB market.

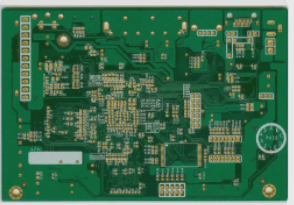

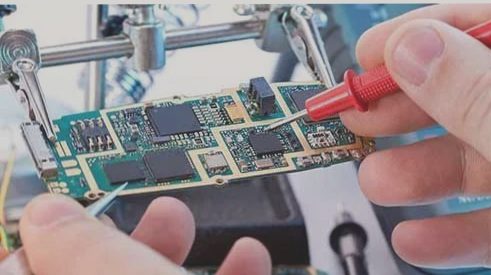

5. Avoid unnecessary board cutting, as this increases PCBA costs without significantly affecting brand recognition or functionality. By continuously conducting rigorous DFM (Design for Manufacturability) reviews to identify commonly implemented circuits, PCB assembly costs can be reduced over time. Enhance the bare PCB’s schematic layout by effectively optimizing the key factors that influence assembly. A good understanding of the factors in the image below can help you better balance order volumes, which can lead to lower unit costs. The more orders placed, the lower the cost per PCB component.

6. Once you understand how the PCB assembler calculates lead time, adjust it accordingly. Address all concerns related to startup time, order dates, payment schedules, parts receipt dates, and other relevant factors. Purposefully choose professional and reliable PCB manufacturers or assemblers. Many PCB assemblers claim to offer cost-effective services, but many customers are dissatisfied because the promised value isn’t delivered. To avoid such issues, consider the following factors when selecting a PCB manufacturer:

7. Look for strong manufacturing capabilities and quality management certifications to ensure high-quality PCB assembly services. Compliance with international standards such as ROHS, ISO9001, UL, and others has become essential for both process improvements and product quality assurance.

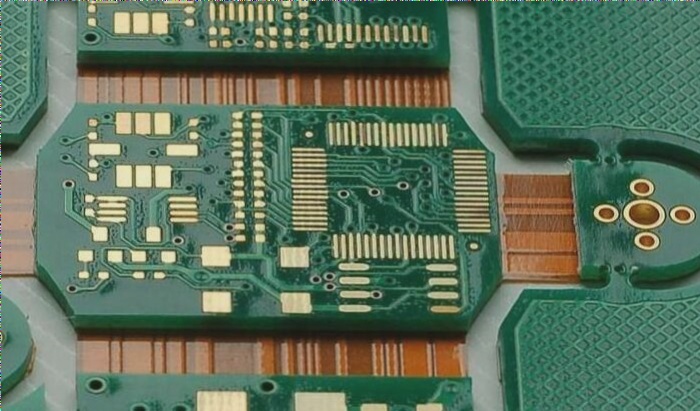

8. The use of advanced equipment, clean tool rooms, and upgraded technologies all contribute to faster turnaround times, high efficiency, required manufacturing speeds, precision placement, and thorough inspection. In today’s fast-paced innovation landscape, leveraging surface mount technology (SMT), through-hole technology, and other specialized PCB techniques should be a top priority when selecting a PCB manufacturer.

If your have any questions about PCB ,please contact me info@wellcircuits.com

1. High costs are a common challenge faced by many industries, and regardless of how the economy improves, numerous American businesses are continuously seeking effective ways to lower costs and improve profit margins, all while maintaining product quality and process development. This is especially true in the electronics industry.

2. One of the most pressing issues for electronics manufacturers and original equipment manufacturers (OEMs) is the rapidly evolving technology, which demands increasingly complex PCB assembly services. To address these challenges, it is essential to uphold quality standards throughout every stage of PCB assembly.

3. Naturally, there is a need to consider strategies for reducing PCB assembly costs without compromising quality. The goal is to streamline the process, simplifying wherever possible, and minimizing PCBA costs as effectively as possible. This is not about overcomplicating the process to make it more compact, versatile, or reliable, but rather finding straightforward solutions to lower expenses.

4. For most electronics manufacturers, identifying the key areas where costs can be safely reduced—while still meeting customer expectations for high-quality products—is not an easy task.

Here is a slightly refined version of your text with improved phrasing, while keeping the meaning, clarity, technical accuracy, and style intact:

—

1. At the same time, balancing project schedules and budgets remains a challenge. On one hand, strict inspection procedures lead to higher costs. On the other hand, neglecting or skipping these inspections in the PCB assembly process can result in even higher costs. So, why not explore simple methods and strategies to achieve greater cost savings?

2. Minimize complexity by offering a range of design options, which can help ensure that the correct prototype is selected from the outset. Streamline the design by applying common structural elements to reduce costs. Complex shapes often result in increased manufacturing expenses.

3. A well-planned and efficient PCB layout is crucial. An essential phase in PCB assembly is the “stealing” process, which requires careful planning to minimize costs. This phase involves the PCB layout design. Through strategic PCB engineering, you can optimize the use of high-quality components, which can significantly reduce the cost per PCB.

4. Allocate sufficient time to create a well-organized and detailed bill of materials (BOM). A complete BOM should include all the essential information, such as reference designators, part numbers, specifications, quality requirements, SMT assembly methods, manufacturer names, component footprints, packaging details, and BOM levels. Most importantly, include component substitutions in the BOM. Given the rapid pace of technological advancements, it’s crucial to replace outdated components with newer alternatives to keep pace with the competitive PCB market.

5. Avoid unnecessary board cutting, as this increases PCBA costs without significantly affecting brand recognition or functionality. By continuously conducting rigorous DFM (Design for Manufacturability) reviews to identify commonly implemented circuits, PCB assembly costs can be reduced over time. Enhance the bare PCB’s schematic layout by effectively optimizing the key factors that influence assembly. A good understanding of the factors in the image below can help you better balance order volumes, which can lead to lower unit costs. The more orders placed, the lower the cost per PCB component.

6. Once you understand how the PCB assembler calculates lead time, adjust it accordingly. Address all concerns related to startup time, order dates, payment schedules, parts receipt dates, and other relevant factors. Purposefully choose professional and reliable PCB manufacturers or assemblers. Many PCB assemblers claim to offer cost-effective services, but many customers are dissatisfied because the promised value isn’t delivered. To avoid such issues, consider the following factors when selecting a PCB manufacturer:

7. Look for strong manufacturing capabilities and quality management certifications to ensure high-quality PCB assembly services. Compliance with international standards such as ROHS, ISO9001, UL, and others has become essential for both process improvements and product quality assurance.

8. The use of advanced equipment, clean tool rooms, and upgraded technologies all contribute to faster turnaround times, high efficiency, required manufacturing speeds, precision placement, and thorough inspection. In today’s fast-paced innovation landscape, leveraging surface mount technology (SMT), through-hole technology, and other specialized PCB techniques should be a top priority when selecting a PCB manufacturer.

If your have any questions about PCB ,please contact me info@wellcircuits.com