Optimizing PCB Manufacturing Process for Efficiency and Quality

Design for Manufacturing (DFM) Principles

DFM is crucial in PCB design, analyzing designs for cost-effective manufacturing within specified constraints. By incorporating DFM principles, engineers can preemptively address manufacturing issues, minimizing rework and production delays.

Standardizing PCB Designs

Standardizing PCB designs can streamline manufacturing. Adopting common formats like Gerber files and IPC-D-356 enables process automation, reducing errors and facilitating communication between designers and manufacturers for accurate design transfer.

Utilizing PCB Design Software

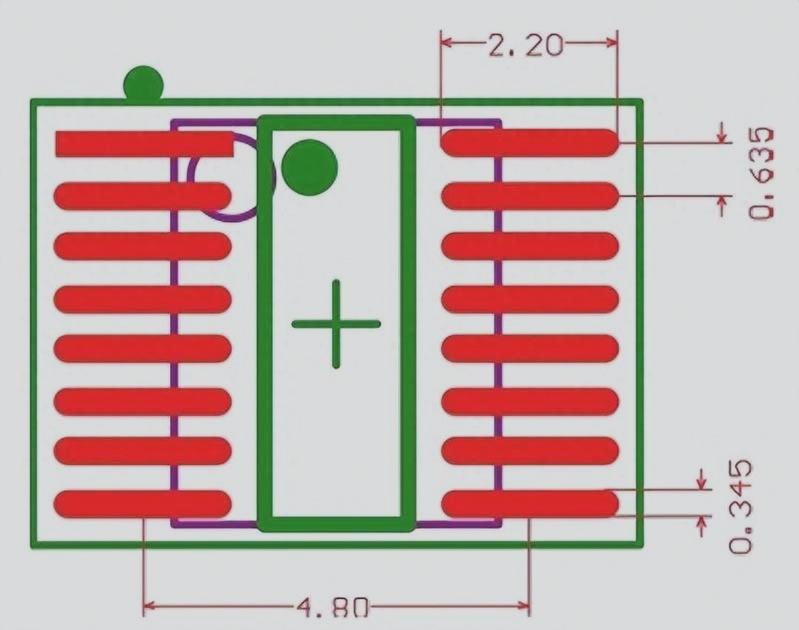

Utilizing PCB design software enhances the manufacturing process by offering advanced features for design, layout, and documentation. Automation of tasks like component placement and routing saves time and reduces errors. Additionally, integrated DFM checks in PCB design software further streamline the design process.

Efficient PCB Fabrication

Streamlining the assembly process is crucial for efficient PCB manufacturing. By optimizing the assembly process, manufacturers can enhance throughput and minimize errors. Consider the following strategies:

- Automated Soldering: Implementing automated soldering systems reduces manual labor and improves accuracy.

- Assembly Line Configuration: Optimizing the arrangement of assembly equipment minimizes downtime and boosts productivity.

- Lean Manufacturing Principles: Applying lean manufacturing principles reduces waste and streamlines the assembly process.

Quality Control Inspections

Regular quality control inspections are vital to ensure the quality and reliability of PCBs during manufacturing. By implementing robust inspection procedures, manufacturers can identify and address issues early, reducing rework and defects. Quality control inspections may include visual inspections, electrical testing, and component analysis.

Enhancing Efficiency and Productivity

Streamlining the PCB manufacturing process requires a combination of effective strategies and techniques. By incorporating DFM principles, standardizing designs, utilizing PCB design software, implementing automated manufacturing systems, optimizing assembly processes, and conducting regular quality control inspections, manufacturers can significantly enhance efficiency and productivity. These strategies not only improve product quality but also reduce costs and lead times, ultimately leading to successful PCB manufacturing.