2. Flux coating system

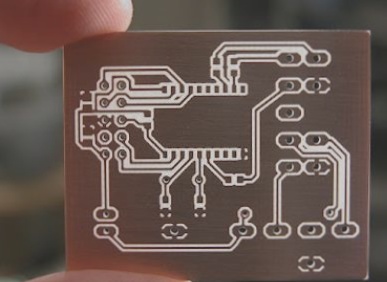

This system is responsible for applying flux to the PCB board before soldering. It consists of a reservoir for holding the flux, a pump for controlling the flux flow, and a nozzle for evenly distributing the flux onto the PCB.

3. Preheating system

The preheating system is essential for ensuring the PCB and components are at the correct temperature before entering the wave soldering process. This system typically consists of infrared heaters or hot air convection systems to heat the PCB evenly.

4. Welding system

The heart of the wave soldering process, this system includes a wave soldering machine that creates a wave of molten solder. The PCB is passed over this wave, which solder the components to the board.

5. Electrical and mechanical structure system

This system includes the electrical and mechanical components that control the entire wave soldering machine. It is responsible for maintaining the correct speed of the conveyor, controlling the wave height and temperature, and ensuring the overall stability of the machine during operation.

By understanding the principle and structure composition of wave soldering, PCB experts can ensure the smooth operation of the machine and the high-quality soldering of PCB boards.

2. Flux Coating System

Various methods are used to apply flux onto PCBs, including foaming agents and sprays.

3. Preheating System

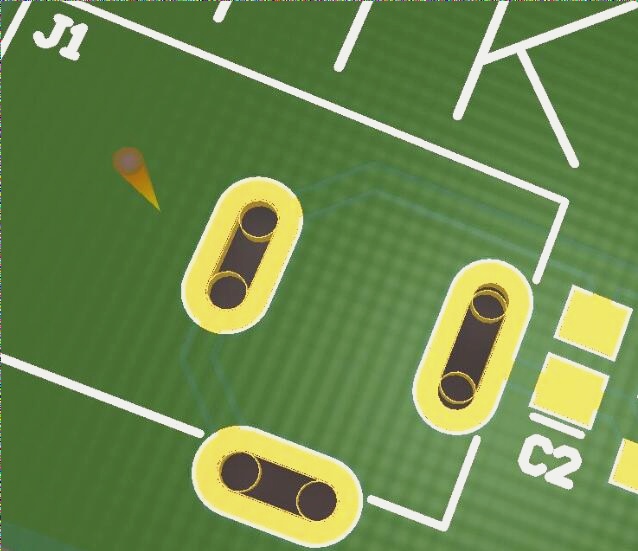

Preheating PCB components at high temperatures can fast volatilize solvents in the flux, activating the flux to remove the oxide layer on the PCB pad and components’ welding ends, laying the foundation for high reliability welding.

4. Welding System

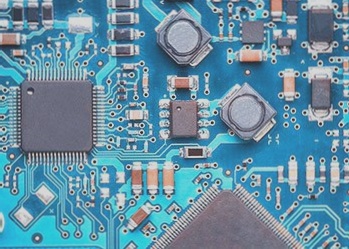

The welding system is a critical part of the wave soldering machine and a key component of the overall welding operation. The basic principle of wave soldering involves utilizing the pump’s stirring action to form a specific wave shape from the molten solder in the solder groove. The PCB with components is then passed through the solder wave at a specific angle and immersion depth to achieve reliable solder joints. Early wave soldering machines had a single outlet, while modern machines have two outlets, known as double wave soldering machines. The shape of the tin wave in the double wave soldering machine’s last outlet is relatively flat, ensuring more even heating and reliable solder joints. Various waveforms have been used in the past, including the λ wave, Ω wave, and bubble tin wave, each with its own advantages and limitations.

Composition Principle of Wave Soldering

Modern wave soldering machines utilize a T-wave shape, ensuring wide wave peaks for sufficient welding time and reduced bridging. Some machines also feature a hot air knife to remove solder joint bridging and reduce thermal stress on components. A cooling fan is installed to quickly cool the PCB after wave soldering.

5. Electrical and Mechanical Structure System

The electrical and mechanical structure system is essential for the effective operation of the above systems. High-performance wave soldering machines offer stable operation, precise quantitative control, and ±1℃ temperature control for preheating and tin pot temperatures. Additionally, rail width, inclination, solder joint depth, and dwell time can be quantitatively controlled. The welding system is the main station in the wave soldering machine, with the rest serving as auxiliary stations that are indispensable for the overall functionality of the machine.

This system is responsible for applying flux to the PCB board before soldering. It consists of a reservoir for holding the flux, a pump for controlling the flux flow, and a nozzle for evenly distributing the flux onto the PCB.

3. Preheating system

The preheating system is essential for ensuring the PCB and components are at the correct temperature before entering the wave soldering process. This system typically consists of infrared heaters or hot air convection systems to heat the PCB evenly.

4. Welding system

The heart of the wave soldering process, this system includes a wave soldering machine that creates a wave of molten solder. The PCB is passed over this wave, which solder the components to the board.

5. Electrical and mechanical structure system

This system includes the electrical and mechanical components that control the entire wave soldering machine. It is responsible for maintaining the correct speed of the conveyor, controlling the wave height and temperature, and ensuring the overall stability of the machine during operation.

By understanding the principle and structure composition of wave soldering, PCB experts can ensure the smooth operation of the machine and the high-quality soldering of PCB boards.

2. Flux Coating System

Various methods are used to apply flux onto PCBs, including foaming agents and sprays.

3. Preheating System

Preheating PCB components at high temperatures can fast volatilize solvents in the flux, activating the flux to remove the oxide layer on the PCB pad and components’ welding ends, laying the foundation for high reliability welding.

4. Welding System

The welding system is a critical part of the wave soldering machine and a key component of the overall welding operation. The basic principle of wave soldering involves utilizing the pump’s stirring action to form a specific wave shape from the molten solder in the solder groove. The PCB with components is then passed through the solder wave at a specific angle and immersion depth to achieve reliable solder joints. Early wave soldering machines had a single outlet, while modern machines have two outlets, known as double wave soldering machines. The shape of the tin wave in the double wave soldering machine’s last outlet is relatively flat, ensuring more even heating and reliable solder joints. Various waveforms have been used in the past, including the λ wave, Ω wave, and bubble tin wave, each with its own advantages and limitations.

Composition Principle of Wave Soldering

Modern wave soldering machines utilize a T-wave shape, ensuring wide wave peaks for sufficient welding time and reduced bridging. Some machines also feature a hot air knife to remove solder joint bridging and reduce thermal stress on components. A cooling fan is installed to quickly cool the PCB after wave soldering.

5. Electrical and Mechanical Structure System

The electrical and mechanical structure system is essential for the effective operation of the above systems. High-performance wave soldering machines offer stable operation, precise quantitative control, and ±1℃ temperature control for preheating and tin pot temperatures. Additionally, rail width, inclination, solder joint depth, and dwell time can be quantitatively controlled. The welding system is the main station in the wave soldering machine, with the rest serving as auxiliary stations that are indispensable for the overall functionality of the machine.