PCB Manufacturing: Understanding the Subtractive Process

Transitioning to Additive Method in PCB Copy Board Design

PCB copy board design and manufacturing are evolving from the subtractive method to the additive method. This shift brings about significant changes in the industry. Let’s delve into the key concepts and manufacturing processes of the PCB subtractive method for a better understanding.

Introduction to PCB Subtractive Process

The subtractive process involves selectively removing parts of the copper foil on the surface of a copper-clad laminate to create a conductive pattern. This method remains the dominant technique in PCB manufacturing due to its maturity, stability, and reliability.

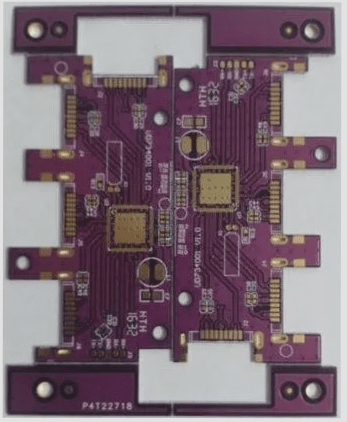

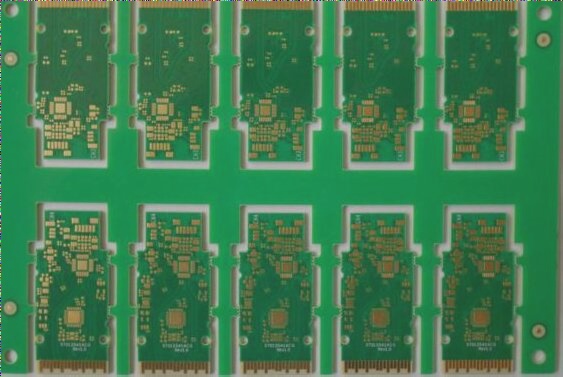

Types of PCBs Manufactured Using the Subtractive Process

- Non-Plated Through-Hole Board (Non-Plated-Through-Hole PCB)

Single-Sided Printed Board

Single-sided printed boards are commonly used in televisions and radios. They are produced through a process involving photochemical methods and screen printing. The production process includes steps such as resist removal, hole processing, solder mask printing, and more.

Plating-Through-Hole Board

Plating-through-hole boards are essential for applications like computers and mobile phones. These boards involve electroless plating and electroplating to create electrical connections between conductive patterns. The process includes pattern plating and full-board plating methods.

Pattern Plating (Pattern, PIN)

Pattern plating involves creating conductive patterns on double-sided copper-clad laminates through screen printing or photochemical methods. The process includes etching, lead-tin plating, solder mask application, and more.

Full Board Plating (Panel, PNL)

Full-board plating entails plating copper to the required thickness on double-sided laminates. The process includes image transfer, etching, resist removal, and final board formation. Advantages of this method include coating thickness uniformity, while challenges include energy inefficiency.