Applying the appropriate post-processing and surface finishing techniques can significantly enhance the surface roughness, appearance, and wear resistance of CNC machined parts, potentially improving their overall functionality. This article will introduce several common surface treatment methods for metal CNC parts, helping you select the most suitable option for your application.

As Machined

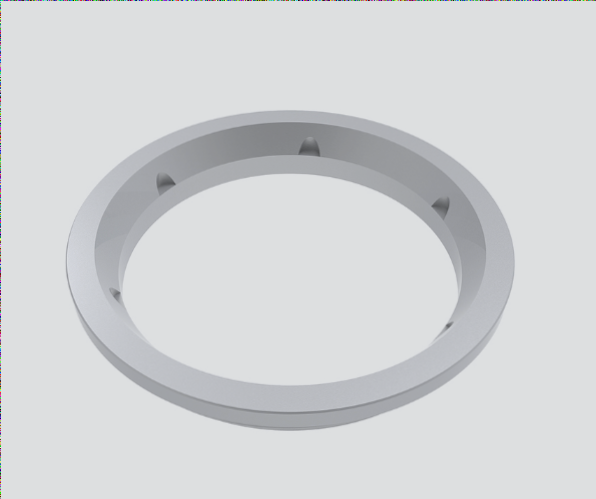

All CNC machined parts will exhibit marks from the cutting tools used during the machining process. Surface quality is measured by average surface roughness (Ra), which represents the average deviation of the machined surface from the ideal. The standard as-machined surface roughness is 3.2 μm (125 μin). After appropriate finishing, surface roughness can be reduced to 1.6, 0.8, or 0.4 μm (63, 32, or 16 μin).

Some materials that affect part dimensional tolerances can be removed through smoothing or polishing the as-machined parts, improving both the surface quality and visual appeal by reducing surface roughness.

Advantages: Achieves the tightest dimensional tolerances;

Disadvantages: Visible tool marks.

Bead Blasting

Bead blasting is a technique used to remove machining marks and achieve a uniform matte or satin surface finish. The process involves using a pressurized air gun to bombard the parts with small glass beads. This method protects critical surfaces or features (such as holes) from dimensional changes while smoothing the part’s surface by removing excess material.

Generally, bead blasting is more commonly used for aesthetic purposes rather than functionality. As it is a manual process, the results depend somewhat on the operator’s skill. Key process parameters include air pressure and bead size, as glass beads come in various sizes.

Advantages: Achieves a uniform matte or satin finish at a low cost;

Disadvantages: May affect critical dimensions and surface roughness.

Anodizing (Type II and Type III)

Anodizing involves applying a thin, durable ceramic layer to the surface of metal parts, which enhances corrosion and wear resistance. The anodizing film is non-conductive and can be dyed in various colors. This treatment is compatible only with aluminum and titanium.

During anodizing (Type II and Type III), the component is submerged in a dilute sulfuric acid solution, and a voltage is applied between the component and the cathode. Electrochemical reactions consume the exposed material, transforming it into hard aluminum or titanium oxide.

By adjusting the current, anodizing time, and the solution’s consistency and temperature, coatings of varying thicknesses and densities can be produced.

Advantages:

- Durable decorative coatings;

- Highly wear-resistant coatings for demanding engineering applications (Type III);

- Can be easily applied to internal cavities and small parts;

- Excellent control over coating size.

Disadvantages:

- Compatible only with aluminum and titanium alloys;

- Relatively more fragile compared to powder coating;

- Type III anodizing is the most expensive of the finishes discussed in this article.

Powder Coating

Powder coating involves applying a thin layer of protective polymer to the surface of parts. It is a robust, wear-resistant surface treatment compatible with all metal materials. When combined with sandblasting, it produces parts with smooth, uniform surfaces and excellent corrosion resistance.

The powder coating process is similar to spray painting. The parts are first coated with an optional phosphating or chromate layer to enhance corrosion resistance. Then, dry powder is applied using an electrostatic “spray” gun and cured at high temperatures, usually in an oven at around 200°C.

Multiple layers can be applied to achieve a thicker coating, with typical thicknesses ranging from 18 μm to 72 μm. A wide range of colors is available for selection.

Advantages:

- Durable, wear and corrosion-resistant coatings for functional applications;

- Higher impact resistance than anodizing;

- Compatible with all metals;

- A variety of color options available.

Disadvantages:

- Not easy to apply to internal surfaces;

- Less precise size control compared to anodizing;

- Not suitable for small parts.

If you have any questions about PCBs or PCBA, please feel free to contact me at info@wellcircuits.com.