China’s PCB Industry Growth and Market Trends

Recent survey reports by Prismark, a leading PCB market analysis organization, indicate that China’s PCB industry is poised for significant growth in the upcoming years. Projections show that between 2012 and 2017, the output value of China’s PCBs is expected to increase at a compound annual rate of 6.0%, reaching a total value of 28.972 billion U.S. dollars by 2017. This growth is set to elevate China’s share of the global PCB market to 44.13%.

Market Shifts and Technology Advancements

The current landscape of the PCB market reflects a shift in consumer electronics preferences from traditional desktops and laptops to mobile devices like smartphones and tablets. This transition has led to a demand for thinner, lighter PCBs with a focus on high-density, multi-layer boards. Moreover, the emergence of wearable products has fueled the need for flexible circuit boards, driving innovation in the industry.

Online Automatic Test Systems for PCBs

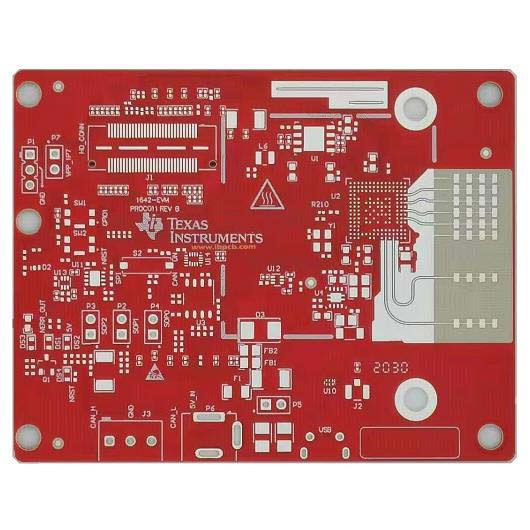

Online automatic test systems play a crucial role in ensuring the quality and functionality of PCBAs. These systems, categorized into In-Circuit Test (ICT) and Functional Test (FCT), are essential components of the manufacturing process.

- ICT: ICT is dedicated to verifying individual component quality and detecting circuit issues within the PCBA. It utilizes advanced technology to pinpoint component faults without assessing the overall functionality of the board.

- FCT: On the other hand, FCT evaluates the overall functionality of the entire PCBA or finished product, ensuring that it meets design specifications and performance standards.

Challenges and Innovations in Testing

As PCB component density continues to increase, testing and inspection face numerous challenges. The integration of PCB circuit boards is advancing to meet the demand for compact, high-performance electronic products. However, the complexity of testing, especially in factory online automatic testing, poses significant obstacles.

Recent years have seen advancements in measurement technologies like TestJet and boundary scan in ICT systems to address these challenges. Despite these enhancements, technical patents and cost factors still influence their widespread adoption.

Conversely, FCT requires comprehensive upgrades to adapt to the evolving landscape of PCBs. With a focus on overall functional testing, FCT is moving towards complete automation to accommodate the diverse and extensive functionalities of modern electronic products.