PCB Board Layout Best Practices for Switching Power Supplies

- Keep connections for pulse voltages short and direct

- Minimize loop area for pulse currents

- Optimize placement of input and output components

- Enhance EMC performance with proper capacitor placement

- Improve output ripple performance with dual capacitors

- Ensure proper spacing and heat dissipation for components

- Pay attention to control section for signal integrity

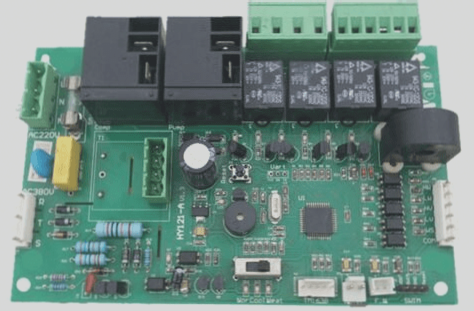

Switching Power Supply Printed Board Design

When designing a PCB for a switching power supply, it is crucial to follow specific wiring principles to ensure optimal performance.

Line Spacing Considerations

- For double-sided boards, maintain a line spacing of 0.3mm

- For single-sided boards, set the line spacing at 0.5mm

- Ensure spacing of 0.5mm for pad-to-pad, pad-to-via, or via-to-via connections

- Adhere to spacing guidelines based on voltage levels

Specific design criteria are essential for modular power supplies, including maintaining minimum distances between components for safety and performance.

Safety Regulations and Clearance

- Maintain clearances based on safety standards

- Ensure proper distances between transformer input wires

- Follow insulation requirements for feedback optocouplers

- Meet clearance requirements for AC input and isolated DC output

Adhering to these best practices will not only improve the efficiency and performance of switching power supplies but also ensure safety and compliance with industry standards.

Common PCB Design Methods

-

Method 1: PCB Slotting

The PCB slotting method is ideal for tight spaces and helps prevent discharge gaps in various applications, such as TV cathode ray tubes and power supplies. It is commonly used in modular power supplies and is effective under potting conditions.

-

Method 2: Pad Insulation Paper

Pad insulation paper, made from materials like phenolic paper and polyester film, provides insulation between circuit boards and metal casings. Different materials offer mechanical strength and moisture resistance, with polytetrafluoroethylene oriented film excelling in high-temperature environments. Insulating films can also enhance insulation resistance between components and conductors.

Certain device insulation covers, like those on electrolytic capacitors, may not reduce safety distances. Adequate space provision is crucial to ensure safe pressure release in extreme conditions.

Precautions for PCB Copper Trace Routing

Most electronic circuits use 35μm copper with a current density of 1A/mm for trace routing. Trace widths should be at least 0.3mm for mechanical robustness. PCB design tools automate adherence to specifications, reducing errors and workload. Different board types offer reliability and cost options, with single-sided boards being cost-effective for general-purpose switching power supplies.

Single-Sided PCB Design Considerations

Single-sided boards are widely used in switching power supplies for their cost-effectiveness. Proper design ensures electrical connectivity and mechanical stability. Enlarged pad sizes and trace connections enhance soldering and mechanical strength. Widening traces at pad junctions prevents breakage, and components should be closely mounted for heat dissipation.

Supporting heavy components with additional connection points and lengthening pins improve solder joint strength. Bending device pins at a 45-degree angle before soldering is a common practice in Taiwan and Japan.

Considerations in Double-Sided Board Design

Advantages of Double-Sided Printed Boards

- Double-sided boards offer superior performance and trace densities.

- Metallized holes enhance pad strength, allowing for smaller solder rings.

- Pad hole diameters can slightly exceed pin diameters to facilitate solder flow through vias.

- Excessively large holes may cause devices to float during wave soldering, leading to defects.

Treatment of High-Current Traces

- Adjust trace widths for high-current handling.

- Tinning traces can increase thickness when widths are insufficient.

- Set pad attributes for traces to ensure they remain uncovered by solder resist during manufacturing.

- Uniform tinning methods for circuit boards are crucial to avoid aesthetic issues caused by uneven soldering.

In conclusion, implementing these strategies can help create robust and efficient PCB designs that meet the demanding requirements of modern electronic applications.