Latest Developments in Tactile Sensing Technology

Recent advancements in tactile sensing technology have revolutionized the capabilities of industrial and commercial robotic systems. These innovations have enhanced the manipulation and grasping abilities of robots, allowing them to interact with objects more effectively across various applications.

New tactile sensors integrated into robot grippers now have the ability to estimate the properties of the objects they handle. By providing robots with a strong sense of interaction forces and contact points, these sensors enable efficient task execution without causing damage or accidents.

One of the latest trends in tactile sensing technology is the integration of artificial intelligence algorithms, which enhance the sensor’s ability to interpret and respond to tactile feedback. This AI-driven approach improves the robot’s adaptability and precision in handling different objects and tasks.

Tactile Sensor Definition and Function

A tactile sensor is a specialized device designed to collect and process information through touch interactions with the environment. These sensors are crucial for replicating the human sense of touch in robotic systems, enabling them to perceive and respond to physical stimuli.

By simulating both the cutaneous and kinesthetic touch senses found in humans, tactile sensors can detect a wide range of stimuli, including pressure, temperature, and mechanical forces. This sensory input is essential for robots to interact safely and accurately with their surroundings.

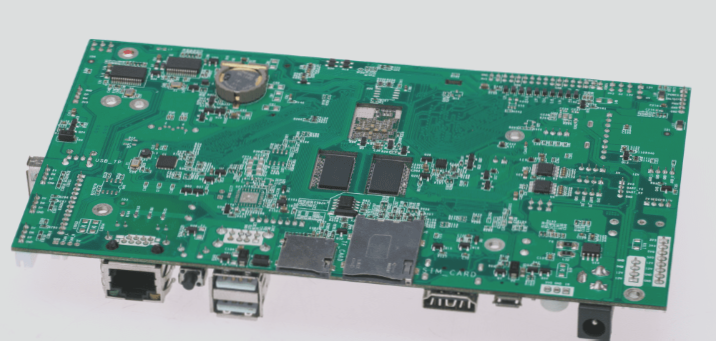

Figure 1: Robot Gripper with Tactile Sensors (Courtesy of Pixabay)

Exploring Tactile Sensor Types and Applications

There are several types of tactile sensors used in robotics and automation:

- Torque/Force Sensor: These sensors, often integrated into tactile arrays, provide precise force control for robotic manipulators. They are crucial for applications requiring accurate force measurement and control.

- Piezoelectric Tactile Sensor: Utilizing the piezoelectric effect, these sensors convert pressure into electrical signals, offering durability and a wide dynamic range for pressure measurement tasks.

- Magnetic Tactile Sensor: Operating based on changes in magnetic flux, these sensors are highly sensitive and free from mechanical hysteresis, making them ideal for various tactile sensing applications.

- Resistive Tactile Sensor: By detecting changes in electrical resistance, these sensors provide reliable and durable tactile feedback, essential for tasks requiring precise pressure sensing.

Each type of tactile sensor plays a unique role in enhancing the capabilities of robots, enabling them to perform intricate tasks with precision and safety.

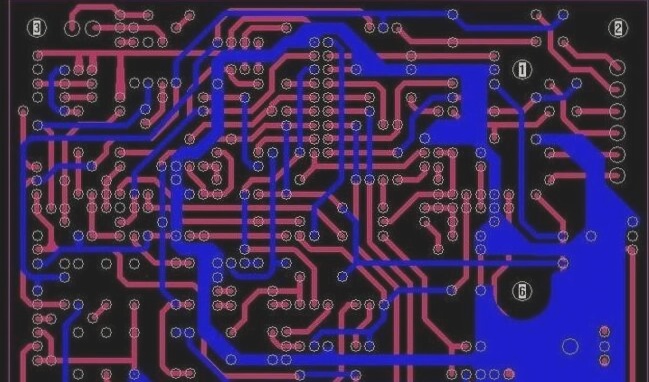

Figure 3: Touch Sensor Calibration Connection (Courtesy of MDPI)

Resistive Tactile Sensor Circuit

A resistive tactile sensor circuit, like the one shown below, is a common type of tactile sensor used in various applications. It detects touch or pressure by changes in resistance.

Figure 5: Circuit of a Resistive Tactile Sensor (Courtesy of Simon Mugo)

Latest Developments in Tactile Sensors

Recent advancements in tactile sensors have led to the introduction of optical and capacitive tactile sensors that offer improved performance and functionality.

Optical Tactile Sensors

Optical tactile sensors utilize light intensity modulation to detect touch or obstacles. They provide high resolution, immunity to electromagnetic interference, and can be operated remotely.

Figure 6: Optical Tactile Sensor Incorporated with Pneumatic Actuation (Courtesy of Simon Mugo)

Capacitive Tactile Sensors

Capacitive tactile sensors measure changes in capacitance to detect touch or pressure. They offer a wider dynamic range and a more linear response compared to resistive sensors.

Figure 7: Capacitive Tactile Sensor Simple Diagram (Courtesy of Simon Mugo)

Role of Tactile Sensors in Robotics

Tactile sensors are vital components in robotics, supporting tasks in various fields, including space exploration. NASA’s robotics and the International Space Station rely on tactile sensors for repairs and operations in space.

Applications and Benefits of Tactile Sensors

Tactile sensors find widespread use in computer hardware, robotics, and touchscreen devices like mobile phones and tablets. Their advantages include:

- Efficient tactile solutions

- Compact design

- Cost-effectiveness due to minimal wiring

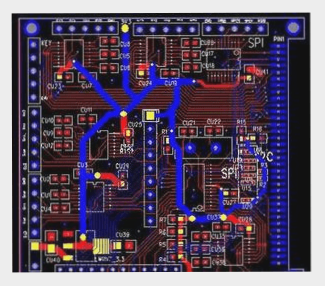

Simulating Tactile Sensors with Proteus EDA Tool

For testing tactile sensor functionality, the Proteus EDA tool offers a simulation environment. Components required for a simple tactile sensor circuit simulation include a touchpad, transistors, resistors, timers, capacitors, and LEDs.

Components Required:

- Touchpad

- BC547 Transistor

- Resistors: 10k, 100k, and 330Ω

- 555 Timer

- Capacitors: 10nF and 10µF

- LED

Simple Tactile Sensor Circuit