The optimal soldering technique for PCBs

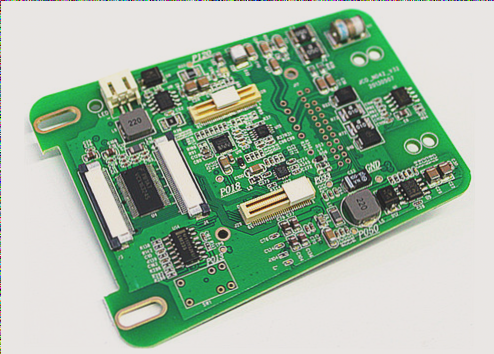

The tin dipping effect in PCB welding involves hot solder forming intermetallic bonds with copper, influenced by surface cleanliness and temperature, while the resulting metal alloy’s properties depend on the welding conditions and the thickness of the alloy layer.