What are the key considerations for selecting a PCBA substrate type?

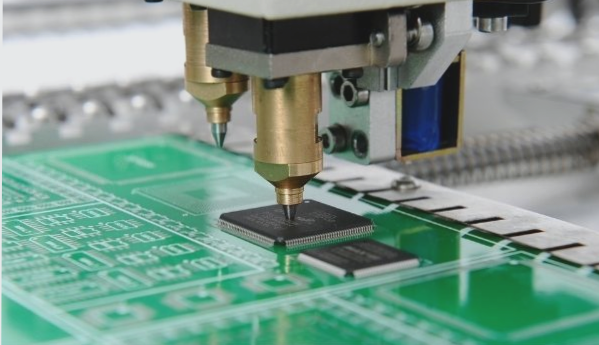

Common types of PCBA substrates include FR-4 boards for their durability, aluminum substrates for effective heat dissipation in LED applications, and flexible FPC boards ideal for high-end devices due to their lightweight and bendable design.

What are the key considerations for selecting a PCBA substrate type? Read More »