Principles of PCB Layout Design and Electromagnetic Interference Mitigation Techniques

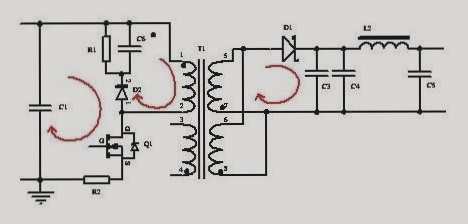

A **Printed Circuit Board (PCB)** serves as the foundation for electronic circuits, and its design plays a crucial role in minimizing interference and optimizing performance, with key considerations including component placement, trace routing, and anti-interference measures.

Principles of PCB Layout Design and Electromagnetic Interference Mitigation Techniques Read More »