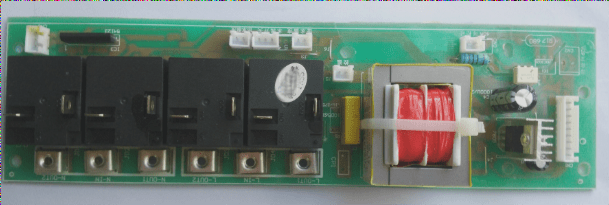

Implement anti-static measures throughout the PCBA processing to ensure optimal performance.

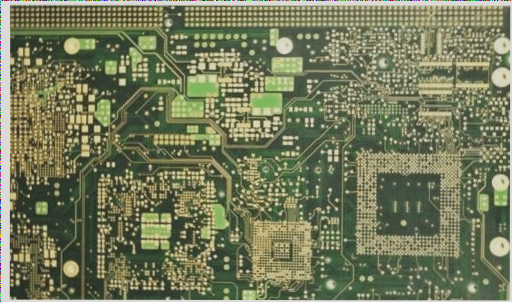

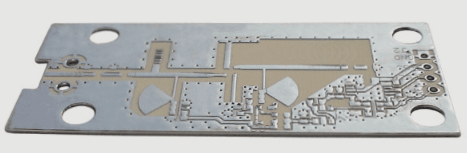

PCB processing requires strict electrostatic protection measures due to the sensitivity of components, necessitating specific anti-static facilities, employee protocols, and operational guidelines to prevent electrostatic discharge.