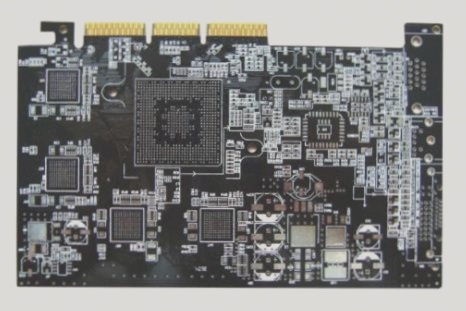

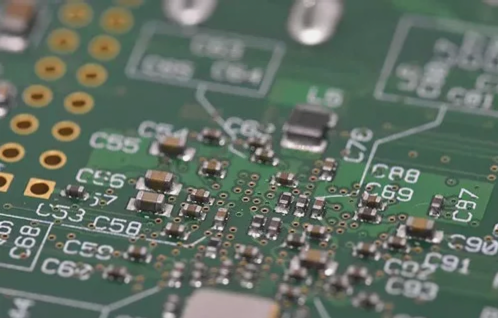

High Speed PCB Via Design

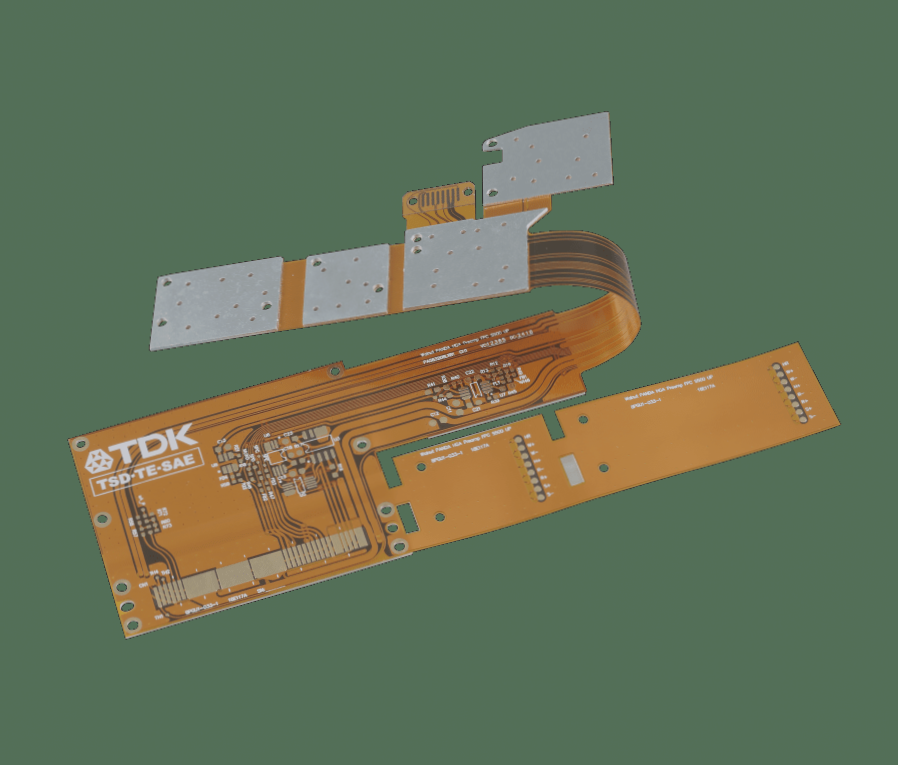

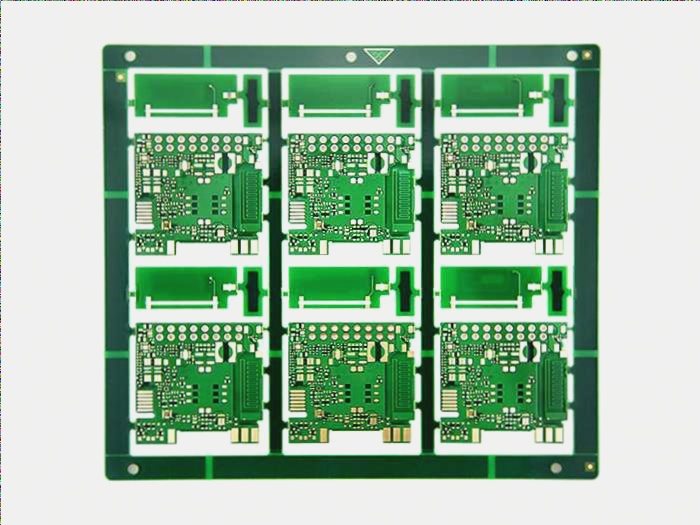

Via design is crucial in high-speed PCBs, impacting signal integrity through considerations of parasitic capacitance and inductance, and necessitating careful selection and optimization of via types and dimensions to meet stringent design requirements.