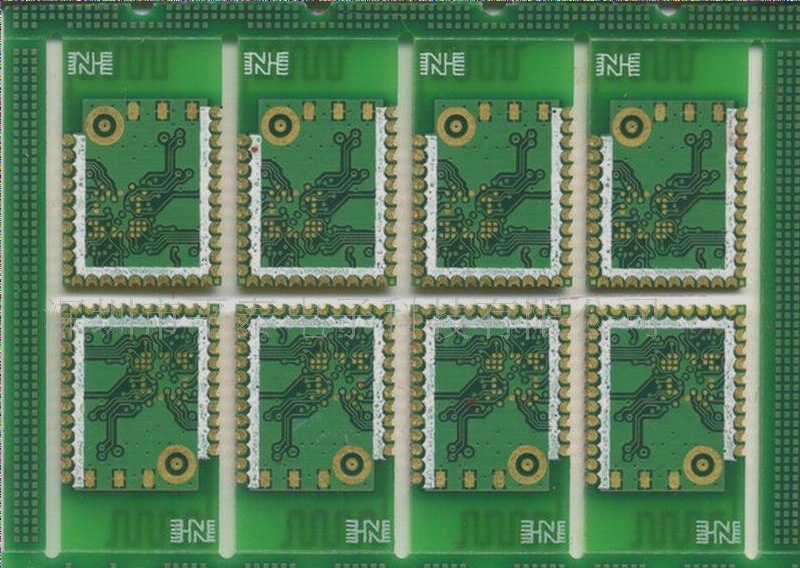

How to assess the quality of PCB ink?

The quality of PCB inks is evaluated through twelve key aspects, including viscosity, plasticity, thixotropy, fluidity, viscoelasticity, drying time, fineness, stringiness, transparency, chemical resistance, physical resistance, and safety/environmental considerations.