Wellcircuit’s New Facility Enhances Our Service Quality – News – Wellcircuits

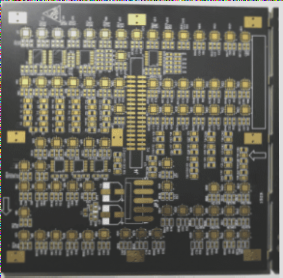

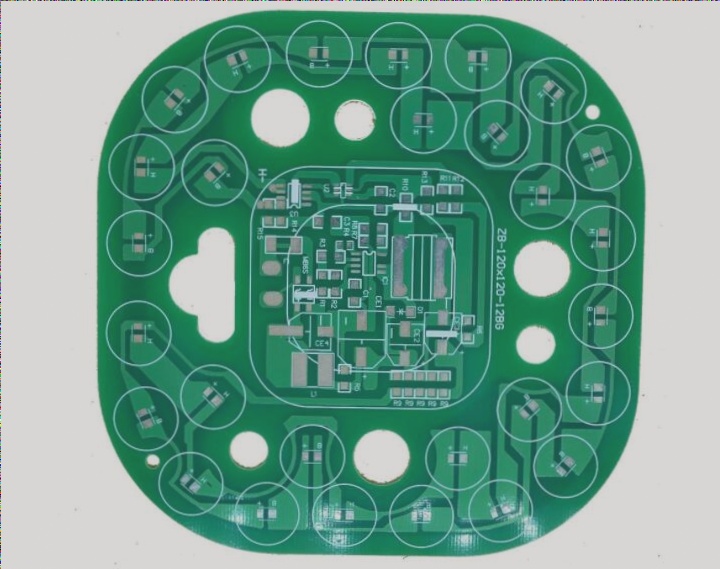

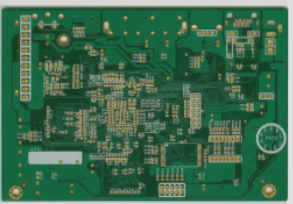

After several months relocation and adjustment our factory finally move to “new home” Please let us take you to roam our new factory The staff can be seen in a hurry immediately on the first floo

Wellcircuit’s New Facility Enhances Our Service Quality – News – Wellcircuits Read More »