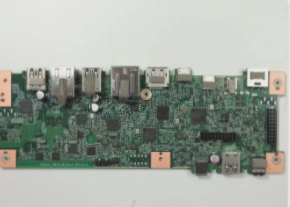

The rationale for blocking the vias on the PCB board.

The evolving production process for printed circuit boards (PCBs) and the importance of via hole plugging to meet increasing demands in surface mount technology (SMT) and ball grid array (BGA) assemblies, detailing various methods for plugging via holes to prevent issues such as solder short circuits, flux residue, and false soldering during wave soldering, with a focus on maintaining technical accuracy and quality control throughout the process.

The rationale for blocking the vias on the PCB board. Read More »