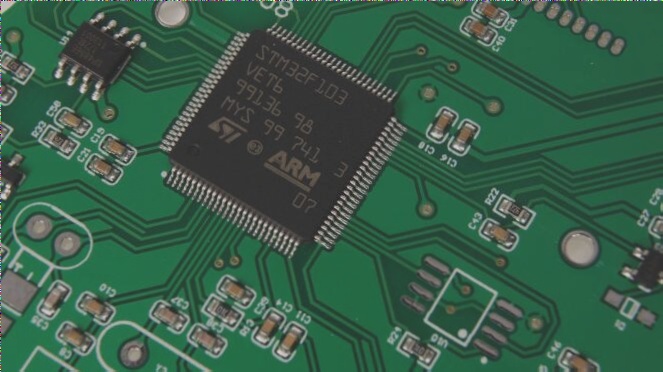

Versatile Applications in Circuit Board Design

A printed circuit board (PCB) is a crucial component in electronics, featuring conductive pathways on an insulating substrate, enabling electrical connections and supporting various electronic components.

العربية

العربية 简体中文

简体中文 Nederlands

Nederlands English

English Français

Français Deutsch

Deutsch Italiano

Italiano 日本語

日本語 한국어

한국어 Português

Português Русский

Русский Español

Español ไทย

ไทย