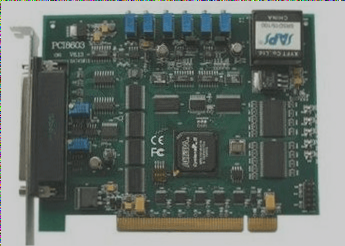

The design, development, and implementation of PCB board-level shielding cavities involve careful consideration of factors such as shielding needs, interference sources, and testing requirements. Various shielding forms, including removable covers and surface mount options, cater to different application demands, balancing cost-effectiveness with performance. Production and assembly methods, including material selection and shielding effectiveness considerations, play crucial roles in achieving optimal shielding performance while managing costs effectively.