Assessing FPC Quality: Criteria for Good vs. Faulty Flexible PCBs

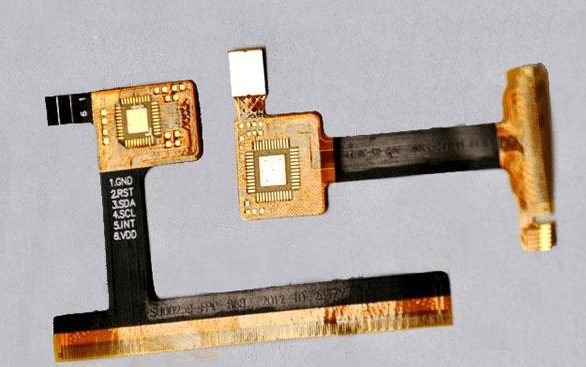

Quality FPC flexible boards must meet size and thickness standards, have proper surface finish and color, exhibit visually appealing weld seam appearance, ensure component functionality, adhere to line specifications, maintain copper adhesion and oxidation resistance, possess electromagnetic compatibility, shape stability, environmental resistance, and mechanical properties.

Assessing FPC Quality: Criteria for Good vs. Faulty Flexible PCBs Read More »