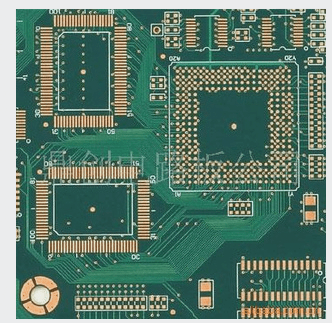

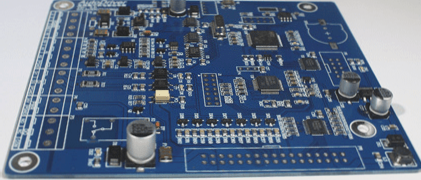

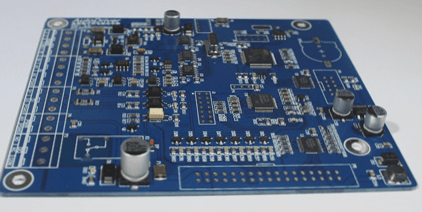

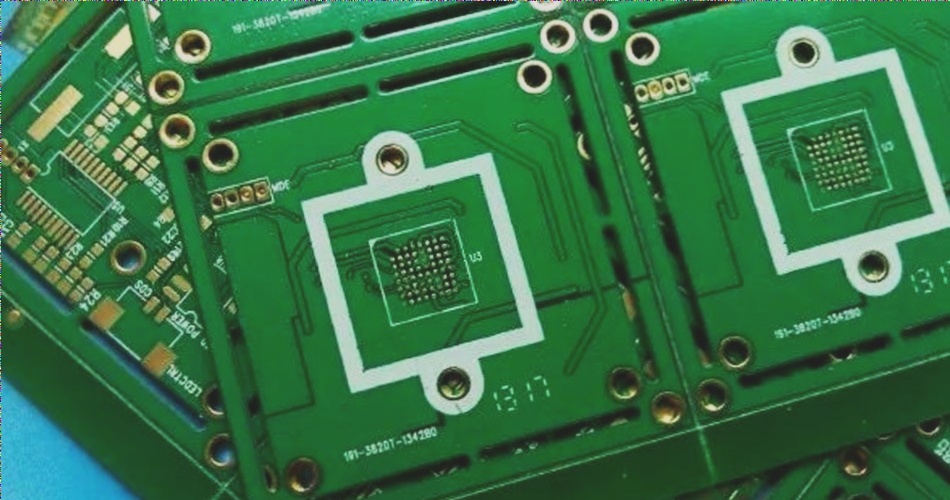

Copper clad printed circuit boards are essential substrates for high-frequency applications. These laminated boards, with copper-clad laminates soaked in resin, are widely used in electronics for their functionality. Their use of glass fiber as a reinforcing material makes them lightweight and ideal for electromagnetic shielding. The significance of copper coating lies in its ability to improve anti-interference and reduce voltage drop, making it advantageous for industries like the military. Copper clad circuit boards play a crucial role in interconnecting, conducting, insulating, and supporting PCBs, significantly impacting signal transmission speed and energy loss. The copper coating is also necessary for grounding, EMI shielding, heat dissipation, copper balance, and providing shorter return paths for high-current equipment. In summary, copper clad circuit boards are the core material for PCB manufacturing, vital for the performance, quality, and reliability of electronic devices.