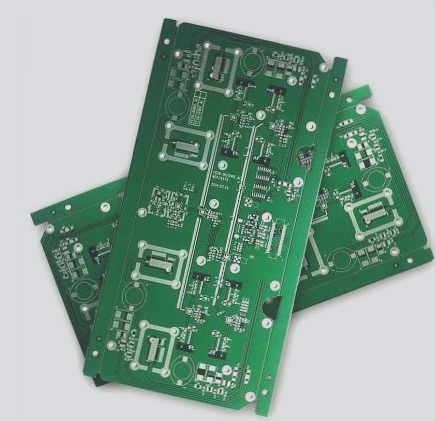

Layer thickness of 6-layer PCB

A 6-layer PCB, also known as a “multi-layer board,” consists of three copper-clad laminates, undergoing cutting and sequential pressing of inner layers with drilled holes, followed by subsequent pressing, drilling, copper electroplating, and is commonly utilized in the communications industry.