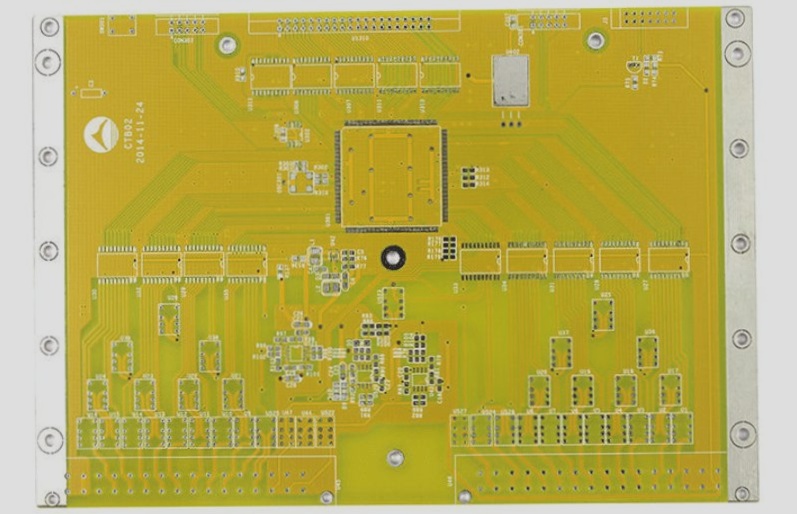

Warpage of PCB circuit boards and its impact on copper foil integrity.

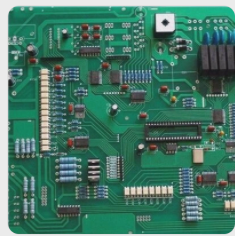

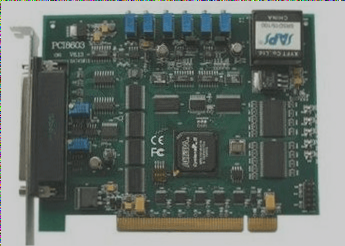

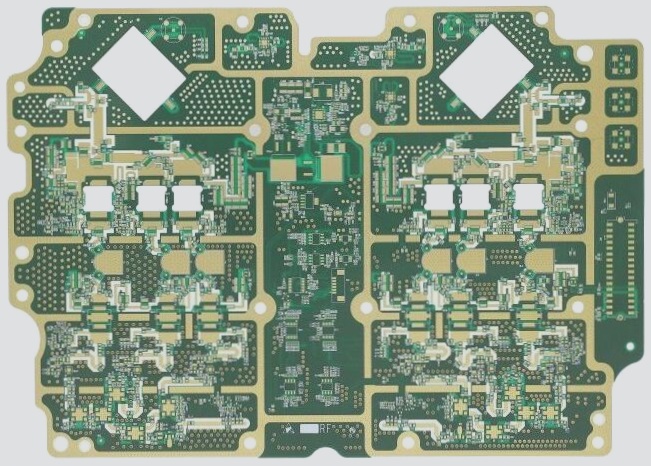

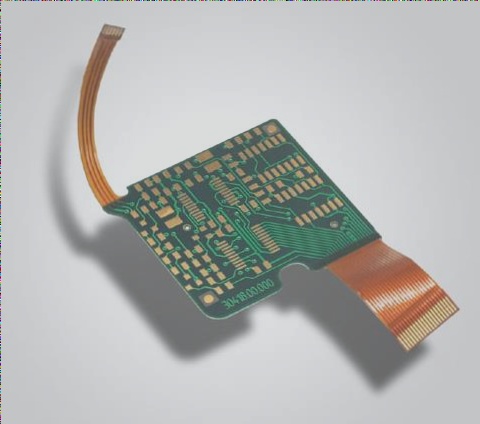

The manufacturing of PCBs involves various heat and chemical treatments that can cause warping, which can be prevented through proper design, processing, and storage, while copper foil plays a critical role in conductivity, electromagnetic shielding, and the growing demand in the electronics industry.

Warpage of PCB circuit boards and its impact on copper foil integrity. Read More »