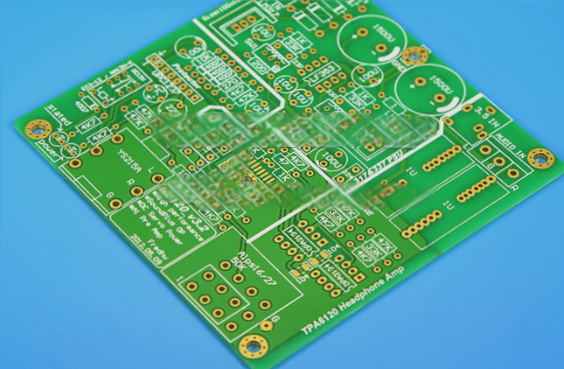

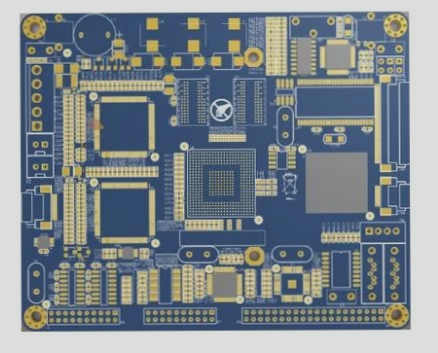

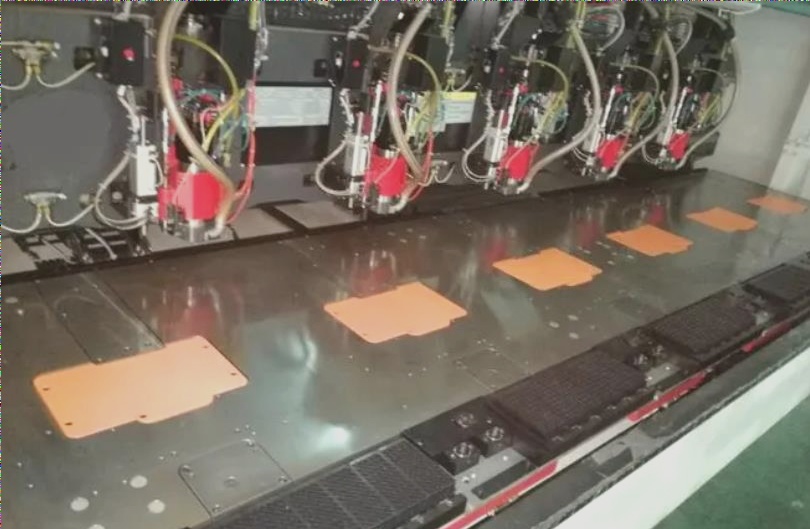

PCB additive manufacturing process

The PCB additive process, driven by the Internet era’s efficiency and environmental sustainability, offers advantages such as cost reduction, faster production, and high-precision manufacturing through techniques like full, semi, and partial additive methods for creating conductive patterns on printed circuit boards.