Distinguishing Between Rogers PCB and FR4 PCB

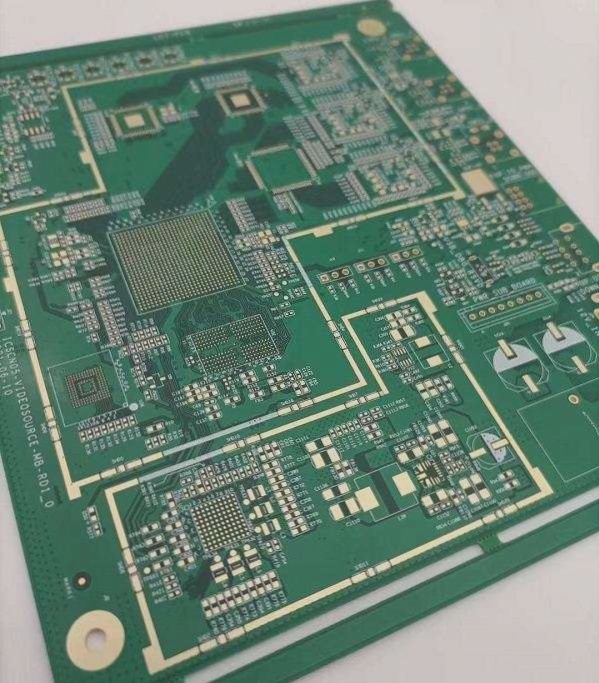

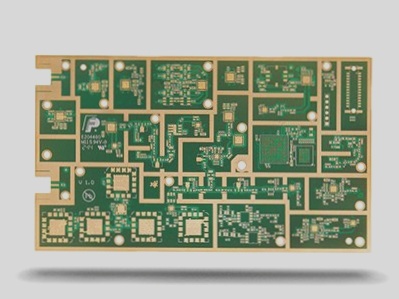

Cost and performance differences between FR4 and Rogers PCBs impact their suitability for various applications, with FR4 being more cost-effective for low frequency and nominal temperature settings, while Rogers PCB is preferred for high-speed or extreme temperature operations due to its superior impedance stability and thermal management capabilities.