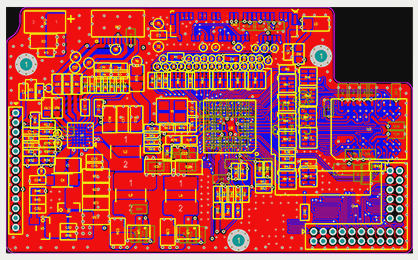

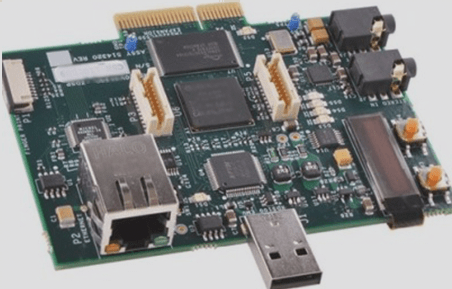

PCB Component Placement and Clearance Analysis

After PCB design, essential inspections include verifying manufacturing requirements, component alignment, 3D graphics, production line optimization, work instructions, inspection rules, and software compatibility to ensure quality and functionality.