Printed Circuit Board Shape Tech

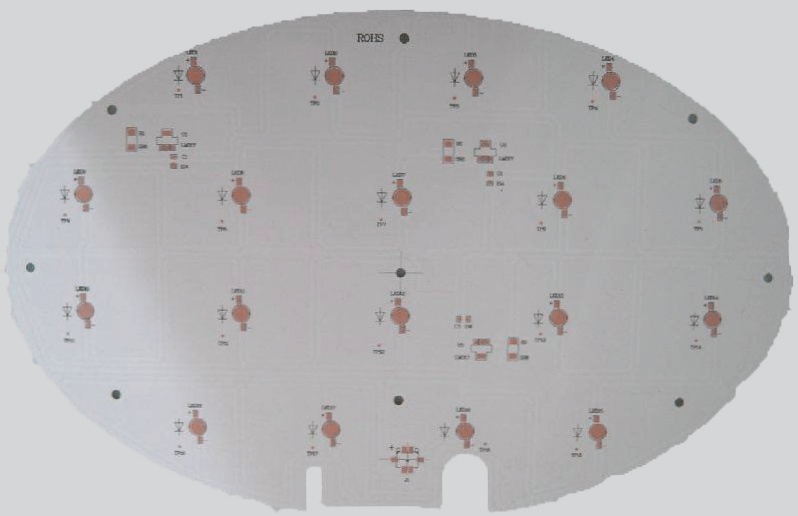

The processing method for printed board shapes involves milling, punching, “V” groove opening, and drilling, selected based on customer needs and batch size, with attention to cutting point selection and tube hole placement for efficiency and optimal shape processing.