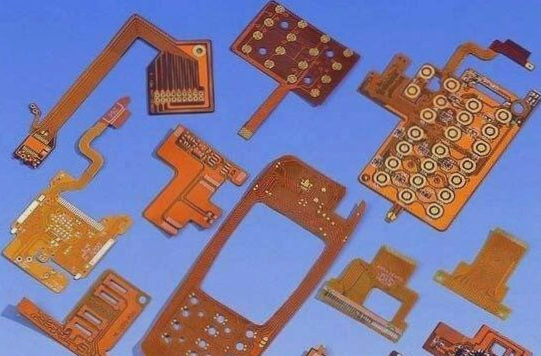

Classification of Multilayer Flexible Printed Circuit Boards (FPCs)

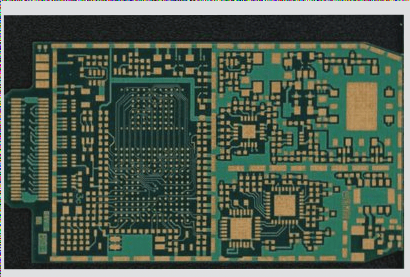

Multilayer FPC soft boards are flexible circuit boards made through multilayer lamination, typically featuring four layers with metallized vias for interconnections, offering lightweight construction and excellent electrical properties, while various designs accommodate different flexibility and reliability needs.

Classification of Multilayer Flexible Printed Circuit Boards (FPCs) Read More »