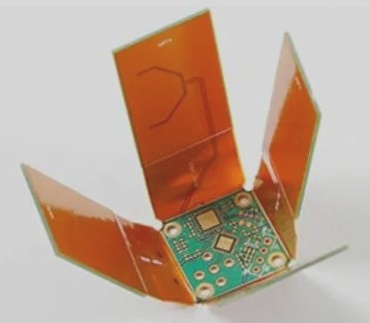

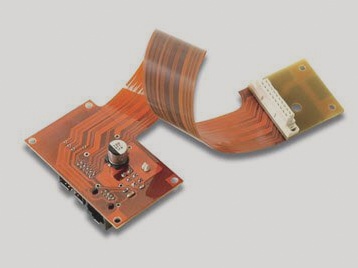

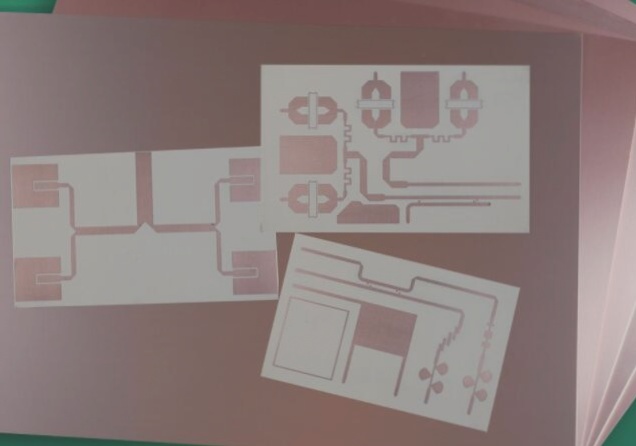

Flex boards and rigid boards are the main materials used in electronic products, with significant differences in physical properties, usage scope, and applicable scenarios. Flex boards are flexible and bendable, suitable for bending and folding scenarios. On the other hand, rigid boards are hard and stable, suitable for durability and stability scenarios. There are also disparities in manufacturing processes, costs, and reliability between flex and rigid boards. Flex boards are relatively simple to manufacture and have lower costs, but lower reliability. Rigid boards are complex to manufacture and have higher costs, but offer higher reliability. Flex boards are used in scenarios requiring greater portability and flexibility, while rigid boards are used in scenarios requiring stability and durability. Understanding the differences and advantages of both can help in choosing the best material for electronic products. As a PCB expert, I can provide assistance in understanding and utilizing flex and rigid boards in electronic products.