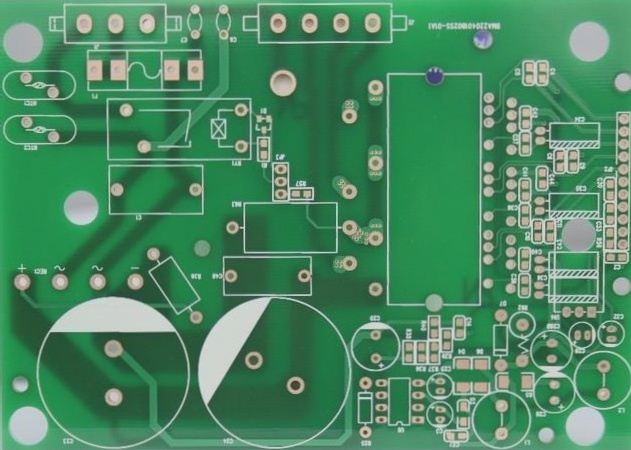

Description and Causes of Deficient Plating in the Electroplating Process

Description and reasons for poor plating during PCB electroplating include recess plating, loose dendritic coating, double-layer plating, blackened coating, passive peeling, replacement peeling, peeling due to oil pollution, dark round spot coating, uneven gloss and thickness, and chemical fiber contamination.

Description and Causes of Deficient Plating in the Electroplating Process Read More »