Everything You Need to Know About FPC Hollow Boards – Essential PCB Information – Wellcircuits

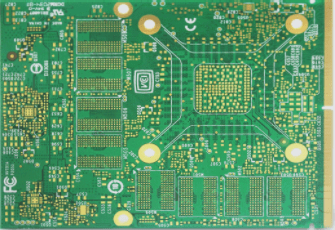

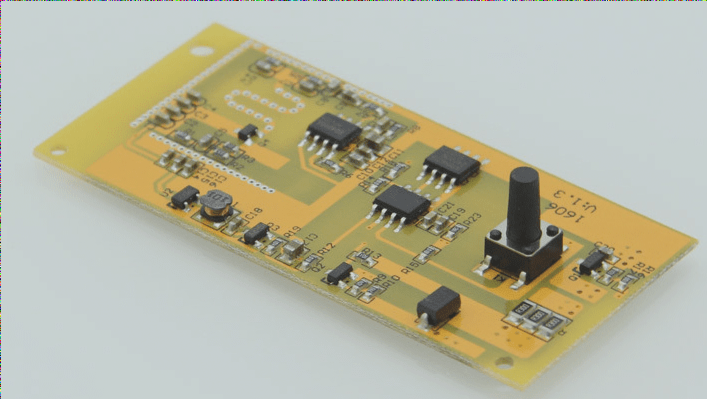

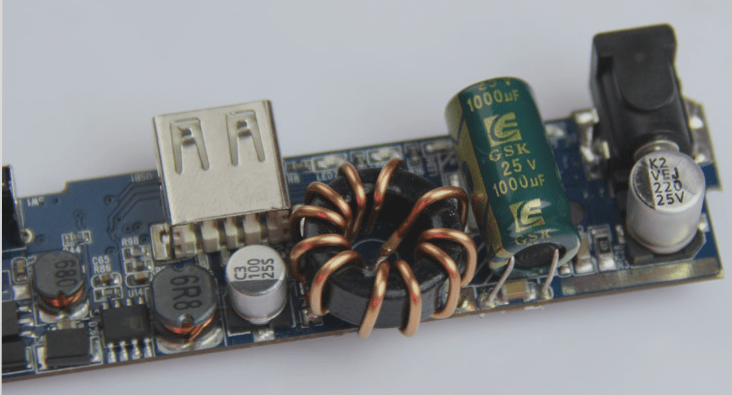

About FPC hollow boardFPC hollowed-out circuit board also known as window circuit board FPC hollowed-out board flexible hollowed-out board ect Hollowed-out FPC board is made by punching etching