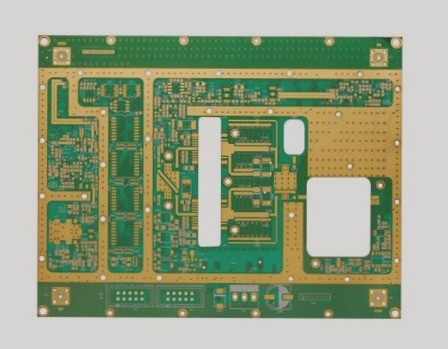

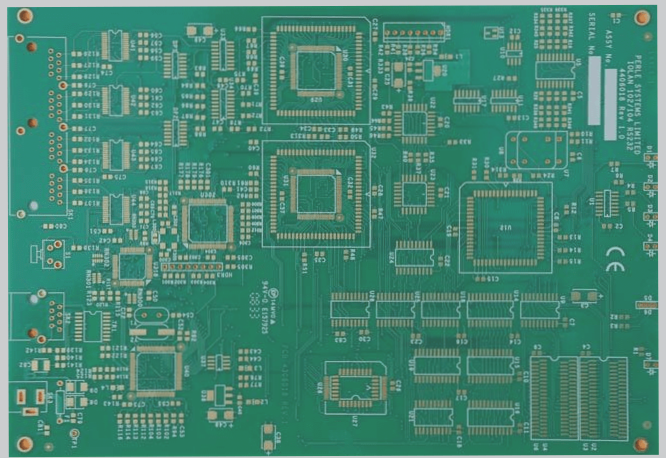

SMT Process for Flexible Printed Circuit Boards (FPC) Assembly

The article discusses the role of Surface Mount Technology (SMT) in the manufacturing of flexible circuit boards (FPCBs), highlighting its benefits such as increased component density, improved reliability, and reduced production costs, while also addressing challenges related to FPCB flexibility and material properties.

SMT Process for Flexible Printed Circuit Boards (FPC) Assembly Read More »